procedure for Replacement of Activated Charcoal

1.0 OBJECTIVE :

1.1 To lay down a procedure for Replacement of Activated Charcoal.

2.0. SCOPE :

2.1 This procedure is applicable to Activated Charcoal Filter situated at Pharma Dekho

3.0. RESPONSIBILITY :

3.1 Operator Engineering Department shall be responsible for replacement of Activated Charcoal and maintaining the record.

3.2 Officer/Executive Engineering Department shall be responsible for to verify the replacement of Activated Charcoal and to take corrective action if any operational deviation.

4.0. ACCOUNTABILITY :

4.1 Head Engineering Department shall be accountable for compliance of SOP.

5.0. PROCEDURE :

5.1 PRIMARY CHECKS:

5.1.1. Ensure that the availability of new carbon.

5.1.2. Ensure that the all pumps shall be switched ‘Off’.

5.1.3. Display the ‘Under Maintenance Board’.

5.2. REPLACEMENT PROCEDURE:

5.2.1 Open the Activated Charcoal filter vessel inlet and outlet connections.

5.2.2 Take out the old Activated Charcoal from the vessel.

5.2.3 Take the new Activated Charcoal in a plastic drum and clean it with fresh water.

5.2.4 Clean the vessel inside with fresh water.

5.2.5 After cleaning of vessel, load the new Activated Charcoal in to vessel.

5.2.6 Connect the vessel inlet and outlet connections.

5.2.7 After closing the vessels, start the plant Ref. SOP No.

5.2.8 Replacement of filtering sand to be carried out once in eighteen months.

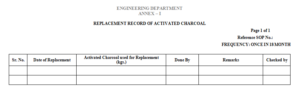

5.2.9 Maintain the log sheet of replacement of filtering sand as par annex –I

6.0 ABBREVIATION :

| Sr. No. | Abbreviation used | Full form of abbreviation used |

| 1. | SOP | Standard operating procedure |

| 2. | EM | Engineering and maintenance |

7.0 ATTACHMENTS (ANNEXES) :

Annex-I : Record for replacement of Activated Charcoal

8.0 REFERENCE :

In House

Annex-I : Record for replacement of Activated Charcoal.

sop for Preventive Maintenance of Liquid Filling and Sealing Machine

sop for Preventive Maintenance of Linear Bottle Washing Machine

sop for Preventive Maintenance of De-Foiling Machine

sop for Preventive Maintenance of Strip Packing Machine

sop for Preventive Maintenance of Blister Packing Machine

sop for Preventive Maintenance of Capsule Polishing and Sorting Machine

sop for Preventive Maintenance of Capsule Filling Machine

sop for Preventive maintenance of Auto Coater

sop for Preventive Maintenance of Compression Machine

sop for preventive maintenance of packing conveyor belt

sop for Preventive Maintenance of Sifter Cum Multi mill

sop for Preventive Maintenance of Rapid Mixer Granulator

sop for Preventive Maintenance Of Fluid Bed Dryer

sop for Preventive Maintenance of Octagonal Blender

sop for Preventive Maintenance of Lifting and Positioning Device

sop for Preventive Maintenance of Paste Preparation vessel

sop for preventive maintenance of Vibro-Sifter

sop for preventive maintenance of air curtain

sop for preventive maintenance of air handling units

Preventive Maintenance of Diesel Generator

sop for Preventive Maintenance of cooling towers

sop for Preventive Maintenance of Boiler

sop for Preventive Maintenance of Air Compressor

sop for Preventive Maintenance of Chilling Plant

sop for Preventive Maintenance of Transformers

sop for Preventive maintenance of Purified Water System

sop for Break Down maintenance of Machine and Work Requisition

sop for Operation of Dust Extraction System

sop for Operation Of Effluent Treatment Plant

sop for Operation Of Diesel Generator

sop for Operation of Multi Column Distillation Plant

sop for Operation of Pure Steam Generator

sop for Operation of Air Handling Unit

sop for Operation of Cooling Tower

sop for Operation of Air Compressor

sop for Operation of Water Chilling Plant

sop for Cleaning of Pure Steam Generator

Cleaning of Over Head Water Tanks HDPE

sop for Cleaning of Water tanks

sop for Sanitization of multi column plant

sop for Sanitization of Ultrafiltration System

Sop for Chemical Sanitization of Reverse Osmosis

Sop for Sanitization of Hot Sanitization & Electro Deionization unit

sop for Sanitization of Purified Water Loop

sop for preparation of sodium meta bisulphate solution

sop for Testing of Hardness of Soft Water

sop for Operation & back wash of multi grade filter

sop for testing of chlorine contents in water

procedure for Replacement of Activated Charcoal