Media Management and Media Preparation

1.0 Objective

To lay down a procedure for Media Management and Media Preparation.

2.0 Scope

This Standard Operating Procedure is applicable for Media Management and Media Preparation to be followed at formulation plants of abc company.

3.0 Responsibility

3.1 Officer / Executive Quality Control are responsible for Media Management and Media Preparation.

3.2 Head Quality control is responsible for the compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

QC : Quality Control

LAF : Laminar Air Flow

HCl : Hydrochloric acid

NaOH : Sodium hydroxide

RODAC : Replicating Organism Detection and Count

GPT : Growth Promotion Test

5.0 Procedure

5.1 Preparation of Culture Media (Using Readymade Dehydrated Media).

5.1.1 Store dehydrated media in tightly closed packs in the dark or as directed by the Manufacturer.

5.1.2 Weight a required amount of dehydrated media and add it to the flask containing purified water.

5.1.3 Make-up the required volume with purified water.

5.1.4 Distribute the media in the flasks or tubes as required. Take 50 ml each media for final

pH check after sterilization.

5.1.5 Cover the flasks and tubes with autoclavable plastic caps / cotton plugs and wrap with

butter paper / aluminum foil.

5.1.6 Media are sterilized in the autoclave at 121.4 ºC for 20 minutes at 15-lbs. pressure unless

otherwise specified. Check the pH of the media after sterilization.

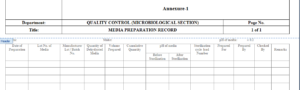

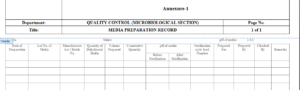

5.1.7 Enter details of prepared media in the ‘Media Preparation Record’ given in Annexure-I.

5.1.8 Also make relevant entries in the autoclave sterilization Record.

5.1.9 Check visually for any growth in the form of turbidity. Discard the media if turbidity observed.

5.2 Preparation of Media Plates:

5.2.1 Rehydrated the medium and sterilize as per the media preparation instructions.

5.2.2 Cool the media and pour in sterile Petri plates (90 mm diameter) under aseptic conditions.

The Petri plates shall be marked on the bottom position with the details of the name of the

medium, load no., date of preparation, Allow to solidify and invert the Petri plates. Pre Incubate

the plates for 48hours at 300C to 350C.

5.2.3 Check visually for any growth in the form of visible growth. Discard the media if any

visible growth is observed.

5.2.4 Store the plates after pre-incubation below 25ºC.

5.3 Preparation of Slants:

5.3.1 After rehydrating the medium dissolve the agar media & makeup the required volume with purified water.

5.3.2 Dispense about 10 ml in test tubes. Plug the tubes with non-absorbent cotton and cover

with a butter paper/Aluminum foil.

5.3.3 Autoclave the media as per SOP & cool the slant on room temperature.

5.3.4 Unload the tubes from the autoclave and place them in a slanting position under LAF.

5.3.5 Ensure that the top of the slant does not touch the cotton plug and allow to solidifying.

5.3.6 Incubate for 48 hours at the 30-35ºC temperature.

5.3.7 Check visually for any contamination. Discard if necessary.

5.3.8 Mark the tubes appropriately with the name of medium, lot no., and preparation date.

5.3.9 Store the slants, after pre-incubation below 25ºC.

5.4 Preparation of RODAC(contact) plates:

5.4.1 Rehydrate the medium and autoclave the media as per SOP.

5.4.2 Cool the media at room temperature and pour in sterile RODAC plates under aseptic conditions.

The RODAC plates shall be marked on the bottom position with the details of the name of the

medium, lot no. and date of preparation.

5.5 Traceability of Media / Sterilization Load Numbers:

5.5.1 Each lot of medium prepared and sterilized is assigned a specific lot number 8 Characters as given below.

xx-yyzzm

xx indicates Serial no. of prepared media

– indicates Hyphen

yy indicates Month

zz indicates Year

m indicates the abbreviation of the media.

5.5.2 All media lots prepared / sterilized are to be serially numbered in month wise.

5.5.3 Record the name of medium and specific lot number of all media used for microbiological

testing in the Analytical Data Sheet.

5.6 Media stock maintenance:

5.6.1 Receive the media from the supplier. Check the bottles/ boxes of media for the Manufacturing

date and expiry date.

5.6.2 Incase the expiry date is within one year (except for the solutions where the expiry date

labeled itself is one year or less), reject the same and send back to the supplier.

5.6.3 Paste the label for the media bottle / box (Refer ANNEXURE-III).

5.6.4 Store dehydrated media in tightly closed packs in the dark or as directed by the manufacturer.

5.6.5 Enter the details of the receipt of the media in the Media Stock register.

5.6.6 Enter the details in such a way that incase there are 2 boxes/ bottles of media of the same

batch 2 lines are allotted for the further record of the same.

5.6.7 The next 2-bottles/ boxes with a different batch number will be entered after that

and 2 lines will be allotted for that batch.

5.6.8 Ensure that the expiry dates of the bottles are in chronological order if more than one batch is received.

5.6.9 Incase there are smaller packets in a box each individual pack shall be labeled.

5.6.10 Ensure that the media stock is used on a First in First Out or First Expiry First Out basis

and that only one pack of medium is in use at any given time.

5.6.11 On opening a new pack, enter the date of opening on the label of the bottle/ box and

in the media stock register.

5.6.12 Follow the media preparation instructions on the label of dehydrate media box.

5.6.13 For each new batch of dehydrated media received, carry out the GPT of the media

as per SOP before using for Microbiological analysis.

5.6.14 Enter the date of release on the label on the pack and in the media stock record on

successful completion of the GPT.

5.7 Retest of The Media Bottles:

5.7.1 Check that the media is having any lumps formation, if any discard the media.

5.7.2 Media containers, which fail in GPT should not be used for testing.

6.0 Forms and Records

6.1 Media Preparation Record – Annexure-1

6.2 Media stock register – Annexure-2

6.3 Label for Media Bottle – Annexure-3

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Control copy – Quality Control

8.0 History

| Revision Number | Details For Change |

Reason for Revision |

| 00 | New SOP | NA |

cleaning and operation of discard autoclave

sop for operation of fogger machine

sop for Biological assay of lactic acid bacillus

sop for preparation of culture inoculum

STP for sterility testing of sterile gloves

sop for Operation and calibration of active air sampler

sop for transfer of material for testing and sampling in sterile area

entry & exit procedure in microbiology laboratory

Growth Promotion Test In Microbiology Laboratory

Operation of B.O.D in Microbiology Laboratory

Operation of Horizontal Laminar Air Flow in the microbiology laboratory

Operation and cleaning of Pass Box.

Operation and cleaning of air sampler

Cleaning and Sterilization of Glassware

Analysis of water for microbial load in microbiology lab

Operation and temperature monitoring of Refrigerator

Fumigation of Microbiology Laboratory.

Entry & Exit procedure In Sterility Area

SOP for Microbial analysis of Raw Material Finished Products

SOP for Operation & Calibration of pH meter in Micro Department

SOP for Operation & Calibration of pH meter in Micro Department

SOP Operation and calibration of Hot Air Oven In Microbiology

SOP for operation cleaning & calibration of Digital colony counter

SOP for Operation And Cleaning of Microscope

sop for Media Preparation and Consumption

sop for Receipt Storage and Usage of Culture Media

sop for Cleaning Sanitization And Disinfection In Microbiology

sop for Environmental monitoring of all the Classified area

sop for Handling and Sub culturing of Microbial cultures

sop for Media Growth Promotion Test and various Microbiological test

sop for BOD incubator operation and cleaning

sop sampling of water for microbiological analysis

sop for Disinfectant Efficacy Test

sop for for cleaning and operation of vortex mixture

sop for Temperature & Relative Humidity Monitoring

sop for Operation and Calibration of Heating Block

sop for Sterility Testing of Microbiology

sop for Disposal of Culture Media

sop for Drain point of Microbiology

sop for entry & exit procedure In Microbial limit test and Biosafety

sop for Gram Staining of Bacteria in Microbiology Laboratory

sop for Monitoring of Compressed Air/gases for microbiological analysis

sop for BET (Bacterial Endotoxin) test in Microbiology

sop for receipt storage and Determining the population of Biological indicators

sop for qualification of analyst microbiologist

sop for Bioburden test of Packing materials in Microbiology Laboratory

sop for microbiological assay of erythromycin antibiotic

sop for liquid particle counter

sop for operation and calibration of digital zone reader

sop for monitoring of ultraviolet efficiency LAF and pass box

microbiological assay of cyanocobalamin or vitamin B12

gowning procedure for microbiological testing area

swab testing of various surfaces for bioburden determination

sop for endotoxin challenge test

Hold time study protocol for sterilized media

sop for personnel Qualification protocol for aseptic area

sop for sampling and testing of drain water

Sop for Operation of Airborne Particle Counter

sop for Validation protocol of steam sterilizer autoclave

sop for pathogen detection from drain point

Sop for Analysis of Raw water Purified water water for injection and pure steam water

sop for preservatives efficacy test

sop for collection and preservation of in house isolated microorganisms

sop for Operation Calibration and Maintenance of Micropipette

sop for microbiological testing of water

sop for depyrogenation of apparatus

sop for fertility test growth promotion test of media

sop for Operation and cleaning of moist heat sterilizer

sop for monitoring by active air sampler

sop for swab sampling and testing for clean rooms in production area

sop for monitoring in microbiology laboratory

sop for Fumigation of aseptic area and microbiology lab

sop for monitoring of personnel in aseptic area

sop for maintenance of cultures

sop for Operation and cleaning of laminar bench

sop for monitoring of pure steam

sop for entry and exit procedure to m.l.t and b.e.t room

sop for storage of and use of media

sop for disposal of microbiological media and cleaning of microbiological glassware

Preparation Filtration Usage and Destruction of Disinfectant Solution

Entry Exit and gowning Procedure in Microbiology Laboratory

Safety measures to be followed in microbiology laboratory

Growth Promotion Test of Media

Preservation and Maintenance of Microbial Strain

Entry and Exit in Microbiology Sterile Area

Entry and Exit in Microbiology Limit testing area

Water sampling of raw water purified water WFI and PSG in microbiology Lab

Microbial monitoring of Drain points

sop for Operation of Double Door Autoclave

Operation and Calibration of Thermo block

Operation and Calibration of Micro pipette

Operation and calibration of BOD-Incubators

Operation and Calibration of Microscope

Operation and Calibration of Air Sampler

Disinfectant Preparation and Cleaning of Microbiology Lab

Operation and cleaning of Static Pass Box

Enumeration of spore count in biological Indicator

Operation and calibration of Conductivity Meter