operation of double door autoclave

1 OBJECTIVE

Double door autoclave is used for sterile zing media, glasswares, equipments, garments, etc. required to be

used in microbiology lab.

2 SCOPE

This procedure is applicable for operation of double door autoclave which is installed in microbiology lab at

ABC pharma .

3 RESPONSIBILITY

Microbiologist.

4 ACCOUNTABILITY

Head- Q.C

5 ABBREVIATIONS

PSG : Pure steam generator.

SOP : Standard operating Procedure

EQ : Equipment

PLC : Programmable Logic Controller

NO. : Number

HPHV : High pressure High vaccum

Q.A : Quality assurance

Q.C : Quality control

6 PRECAUTIONS

6.1 Don’t touch the external surface of autoclave during its sterilization cycle.

6.2 Wear personal protective equipment while unloading the material.

6.3 Always stand on right side while opening the door to avoid direct steam blast on the person.

6.4 After closing the autoclave door check that the door is locked properly so that the door does not open by

the pressure.

6.5 Always open the incoming steam valve gradually.

6.6 If the safety valve blows off, close the incoming steam and air valves immediately.

6.7 Before loading, ensure that autoclave chamber is clean and empty.

6.8 Before running VLT cycle ensure that the temperature of autoclave should not be more than 40°C.

7 MATERIAL REQUIRED

Washed Dress, Media, Glassware’s, Status label for sterilized material, Sterilization indicator.

8 EQUIPMENTS REQUIRED

8.1 SS containers, Filter assemblies.

8.2 UTILITIES REQUIRED

Pure steam, Compressed air, Cooling water.

9 PROCEDURE

9.1 Ensure that proper utility supplies, i.e. Pure steam, Cooling water and compressed air are available and the

Double door autoclave is externally and internally clean.

9.2 Switch “ON” the main power supply & then Control start switch on the panel board of the double door

autoclave.

9.3 Manually open nonsterile side door-1.

9.4 Ensure that unloading side door-2 is closed. Then Load the equipments, materials or garments for sterilizing

in the double door autoclave chamber after proper wrapping with 20 micron aluminum foil or butter paper.

Then close door-1 manually.

9.5 Ensure that both the doors are showing closed indication.

9.6 Put on the Auto/Manual switch on the “AUTO MODE”. First the name of the manufacturer will be displayed,

then press “F2” for login & enter login password “1111” & then press “ENTER”.

9.7 Press F4 for go to main screen on the PLC.The following programm will be displayed.

| Key | Programms | Pressure | Sterilization hold

temperature |

Time

(in minutes) |

| F1 | Standard-01 (Media sterilization) | 1.2 Kg/cm2 | 121°C | 20 |

| F1 | Standard-02 (Media sterilization) | 0.8 Kg/cm2 | 115°C | 15 |

| F2 | Bowie-Dick test | 1.2 Kg/cm2 | 121°C | 17 |

| F3 | HPHV | 1.2 Kg/cm2 | 121°C | 30 |

| F4 | Vacuum leak test | 1.2 Kg/cm2 | – | 10 |

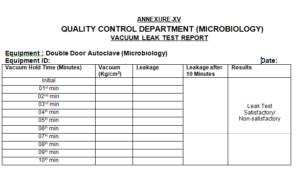

PROCESS FOR VACUUM LEAK TEST CYCLE:

9.8 Press F4 for Vacuum Leak test program for testing the leakage of autoclave chamber and select up arrow

key key to run.

9.9 Check that the printer is “ON” & Press “F1” for Process start”.

9.10 Vacuum pump motor will start and vacuum line solenoid valve will also open. The air from the chamber will

be evacuated from the chamber.

9.11 When the chamber pressure will reach -0.700bar, the vacuum solenoid valve will shut off and vacuum

pump will stop, and the vacuum will stabilized for 02 minutes.

9.12 After vacuum stabilization “VLT Vacuum HOLD” starts and maintained for 10 minutes.

9.13Note down the initial vacuum level and leakage after every one minute of interval in vacuum leak test report.

9.14 After the completion of vacuum hold, the sterile air enter into the chamber automatically through the

chamber vent for breaking the vacuum of the chamber. Chamber pressure drops upto -0.08bar.

After this PLC will show ”END OF CYCLE”

9.15 Take printout of thermograph chart of cycle, Verify and attach the printout in the file.

9.16 In case of leakage over the limit (Equal to or more than 0.0013 bar/min) immediately inform to QC

Manager and Maintenance Head for necessary action.

PROCESS FOR HPHV STERILIZATION CYCLE

9.17 Press F3 for HPHV program for sterilization of dresses, glasswares and equipments & select up arrow key

to run.

9.18 Check that the printer is “ON” & Press “F1 ”for Process start”.

9.19 Ensure the set parameters on the PLC for HPHV-cycle.

i. Sterilization temperature: 121°C (Limit 121-1240 C)

ii. Sterilization hold time: 30 minutes.

iii. Jacket pressure:1.2 Kg/cm2

iv. 3 pre pulsing cycles.

9.20 The process will start automatically, now open the jacket inlet valve and the jacket is pressurized at the

preset pressure, i.e. 1.2 Kg/cm2.

9.21 Vacuum pump motor will start and vacuum line solenoid valve will also open. The air from the chamber will

be evacuated from the chamber. This operation will be repeated for three times.

9.22 After 3 pulsing cycles are over, the vacuum solenoid valve will shut off and vacuum pump will stop.

The steam will enter the chamber to break the vacuum. The heating phase starts. The chamber will be

pressurized with the steam up to the set value of sterilization temperature, i.e. 121°C.

9.23 When chamber reaches to the set temperature 121˚C and chamber pressure is 1.2Kg/cm², the

STERILIZATION HOLD period starts, which is maintained for 30 minutes.

9.24 At the interval of 5 min check and monitor the chamber steam pressure and temperature on the PLC,

gauges and the printer and ensure that all the parameters are within the specified limits as per the

parameters set on the PLC.

9.25 After the sterilization hold period is over, the steam supply solenoid valve shuts off and the Chamber

exhaust solenoid valve opens and steam from the chamber gets exhausted to the atmosphere and the

pressure drops to atmospheric pressure.

9.26 The chamber exhaust solenoid valve will shut off & vacuum pump motor will start and vacuum line

solenoid valve will also open and get post vaccum automatically for 5 minutes.

9.27 After the completion of post vaccum pulse, the sterile air enters into the chamber automatically through the

chamber vent filter for breaking the vacuum of the chamber of the sterilizer. Chamber pressure drops upto

-0.08bar. After this display will show “END OF CYCLE”.

9.28 After “END OF CYCLE” when chamber pressure of double door autoclave reaches upto the 50˚C, wear

personal protective equipments and open the sterile side door 2. Remove the sterilized items and keep at

proper place.

9.29 Take printout of sterilization cycle from printer and also take print out of thermograph chart, Verify and

attach the printout in the file.

9.30 Clean the autoclave with a fine duster from inside the chamber. Close the sterile side door 2 manually.

9.31 Take remedial action, in case of any problems, such as steam pressure of the jacket or chamber

pressure decreases, which will be indicated by hooter. In case of any major problem, switch off the

Sterilizer, first by pressing the Process abort switch and then press the emergency switch.

9.32 Stop the pure steam, cooling water and air supply of the sterilizer when sterilizer is not working.

9.33 Switch “OFF” the Process start switch on the panel board of the Double door autoclave.

9.34 Switch “OFF” the Control start switch on the panel board of the Double door autoclave.

PROCESS FOR STANDARD CYCLE (media)

9.35 Press F1 for standard cycle for sterilization of media & other liquid things, then select arrow key to run.

9.36 Check that the printer is “ON” & Press “F1”for Process start”.

9.37 Ensure the set parameters on the PLC for standard-cycle.

i. Sterilization temperature 121°C (Limit 121-1240 C)

ii. Sterilization hold time 20 minutes.

iii. Jacket pressure 1.2 Kg/cm2

9.38 The process will start automatically, now open the jacket inlet valve and the jacket is pressurized at the

pre Set pressure, i.e. 1.2 Kg/cm2.

9.39 Then heat up starts and chamber will be pressurized with the steam up to the set value of sterilization

temperature 121˚C and pressure 1.2 kg/ cm2.

9.40 When chamber reaches the set temperature and pressure the sterilization hold up period a start, which is

maintained for 20 minutes.

9.41 At the interval of 5 min check and monitor the chamber steam pressure and temperature on the controller

and gauges and the printer and ensure that all the parameter are within the specified limits as per the

parameters set on the PLC.

9.42 After the sterilization hold period is over, the steam supply solenoid valve shuts off and the chamber

exhaust solenoid valve will open and steam from the chamber will be exhausted to the atmosphere and

the pressure drops upto -0.08bar. After this display will show “END OF CYCLE”.

9.43 After “END OF CYCLE” when chamber pressure reaches upto the 50˚C, Wear Personal protective

equipments and open the sterile side door 2. Remove the sterilized items and keep at proper place.

9.44 Take printout of sterilization cycle from printer and also take print out of thermograph chart,verify and

attach the printout in the file.

9.45 Clean the autoclave with a fine duster from inside the chamber. Close the sterile side door 2 manually.

9.46 Take immediate action, in case of any problems, such as steam pressure of the jacket or chamber

pressure decreases, which will be indicated by hooter. In case of any major problem, switch off the

sterilizer, first by pressing the “Process Abort” switch and then press the emergency switch.

9.47 In case of major problem:-

9.47.1 Stop the pure steam and air supply of the sterilizer when Double door autoclave is not working.

9.47.2 Switch “OFF” the Process start switch on the panel board of the Double door autoclave.

9.47.3 Switch “OFF” the Control start switch on the panel board of the Double door autoclave.

PROCESS FOR STANDARD-02 CYCLE (Rappaport Vassiladis Salmonella Enrichment Broth)

9.48 Press F1 for standard cycle for sterilization of media & other liquid things, then select arrow key to run.

9.49 Check that the printer is “ON” & Press “F1”for Process start”.

9.50 Ensure the set parameters on the PLC for standard-cycle.

i. Sterilization temperature 115°C (Limit 115-1180 C)

ii. Sterilization hold time 15 minutes.

iii. Jacket pressure 0.80 Kg/cm2

9.51 The process will start automatically, now open the jacket inlet valve and the jacket is pressurized at the

pre Set pressure, i.e. 0.80 Kg/cm2.

9.52 Then heat up starts and chamber will be pressurized with the steam up to the set value of sterilization

temperature 115˚C and pressure 0.80 Kg/cm2.

9.53 When chamber reaches the set temperature and pressure the sterilization hold up period a start, which is

maintained for 15 minutes.

9.54 At the interval of 5 min check and monitor the chamber steam pressure and temperature on the controller

and gauges and the printer and ensure that all the parameter are within the specified limits as per the

parameters set on the PLC.

9.55 After the sterilization hold period is over, the steam supply solenoid valve shuts off and the chamber

exhaust solenoid valve will open and steam from the chamber will be exhausted to the atmosphere and

the pressure drops upto -0.08bar.After this display will show “END OF CYCLE”.

9.56 After “END OF CYCLE” when chamber pressure reaches upto the 50˚C, Wear Personal protective

equipments and open the sterile side door 2. Remove the sterilized items and keep at proper place.

9.57 Take printout of sterilization cycle from printer and also take print out of thermograph chart, verify and

attach the printout in the file.

9.58 Clean the autoclave with a fine duster from inside the chamber. Close the sterile side door 2 manually.

9.59 Take immediate action, in case of any problems, such as steam pressure of the jacket or chamber pressure

decreases, which will be indicated by hooter. In case of any major problem, switch off the sterilizer, first by

pressing the “Process Abort” switch and then press the emergency switch.

9.60 In case of major problem:-

9.60.1 Stop the pure steam and air supply of the sterilizer when Double door autoclave is not working.

9.60.2 Switch “OFF” the Process start switch on the panel board of the Double door autoclave.

9.60.3 Switch “OFF” the Control start switch on the panel board of the Double door autoclave.

10 FREQUENCY

Vacuum Leak Cycle- Once in a day (First Cycle)

Standard-01 (Media sterilization) – As per Requirement

Standard-02 (Media sterilization) – As per Requirement

HPHV – As per Requirement

Bowie-Dick test- For validation period

11 ENCLOSURES

Annexure I, – Material Loading Pattern

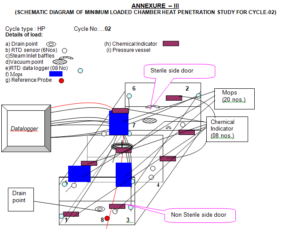

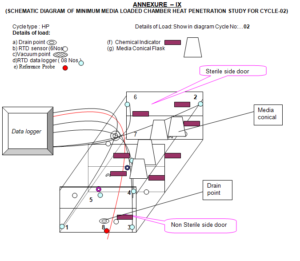

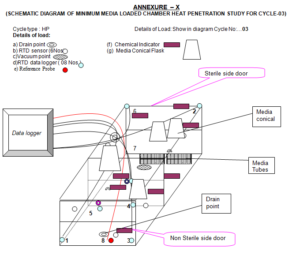

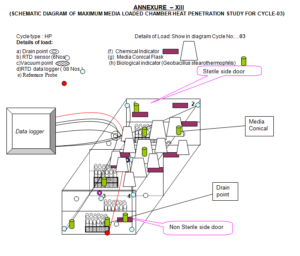

Annexure II, III, IV – Sch. Dia. Of Min. Loaded Chamber Heat Penetration Study For Cy-01 to Cy-03.

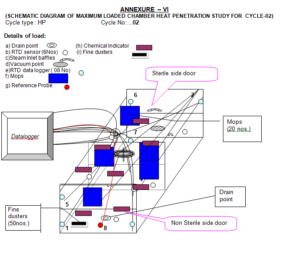

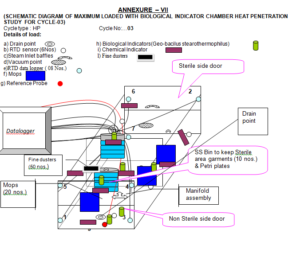

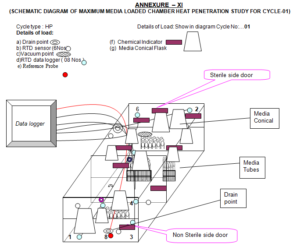

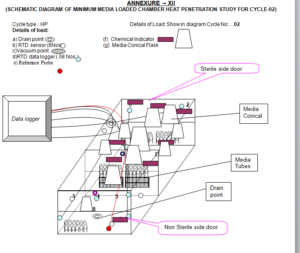

Annexure V, VI, VII – Sch. Dia. Of Max. Loaded Chamber Heat Penetration Study For Cy-01 to Cy-03.

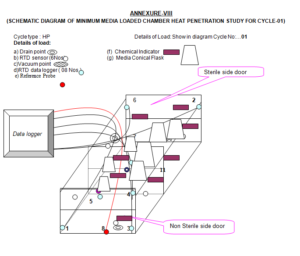

Annexure VIII, IX, X – Sch. Dia. Of Min. Media Loaded Chamber Heat Penetration Study For Cy-01 to Cy-03.

Annexure XI, XII, XII – Sch. Dia. Of Max. Media Loaded Chamber Heat Penetration Study For Cy-01 to Cy-03.

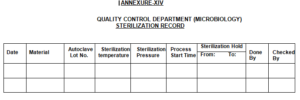

Annexure XIV – Double Door Autoclave Sterilization Record Format.

Annexure XV – Vacuum Leak Test Report Format.

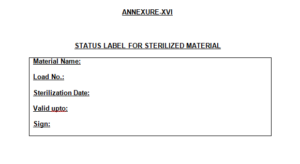

Annexure XVI – Status label For Sterilization Material.

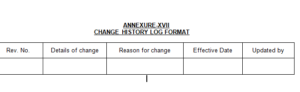

Annexure IV – Change History Log Format.

12 REFERENCE DOCUMENTS

1- Instrument operating manual provided by the manufacturer of Autoclave.

2- Pharmacopoeia.

sop for calibration and validation of micro autoclave

sop for Sterility failure investigation

cleaning and operation of discard autoclave

sop for operation of fogger machine

sop for Biological assay of lactic acid bacillus

sop for preparation of culture inoculum

STP for sterility testing of sterile gloves

sop for Operation and calibration of active air sampler

sop for transfer of material for testing and sampling in sterile area

entry & exit procedure in microbiology laboratory

Growth Promotion Test In Microbiology Laboratory

Operation of B.O.D in Microbiology Laboratory

Operation of Horizontal Laminar Air Flow in the microbiology laboratory

Operation and cleaning of Pass Box.

Operation and cleaning of air sampler

Cleaning and Sterilization of Glassware

Analysis of water for microbial load in microbiology lab

Operation and temperature monitoring of Refrigerator

Fumigation of Microbiology Laboratory.

Entry & Exit procedure In Sterility Area

SOP for Microbial analysis of Raw Material Finished Products

SOP for Operation & Calibration of pH meter in Micro Department

SOP for Operation & Calibration of pH meter in Micro Department

SOP Operation and calibration of Hot Air Oven In Microbiology

SOP for operation cleaning & calibration of Digital colony counter

SOP for Operation And Cleaning of Microscope

sop for Media Preparation and Consumption

sop for Receipt Storage and Usage of Culture Media

sop for Cleaning Sanitization And Disinfection In Microbiology

sop for Environmental monitoring of all the Classified area

sop for Handling and Sub culturing of Microbial cultures

sop for Media Growth Promotion Test and various Microbiological test

sop for BOD incubator operation and cleaning

sop sampling of water for microbiological analysis

sop for Disinfectant Efficacy Test

sop for for cleaning and operation of vortex mixture

sop for Temperature & Relative Humidity Monitoring

sop for Operation and Calibration of Heating Block

sop for Sterility Testing of Microbiology

sop for Disposal of Culture Media

sop for Drain point of Microbiology

sop for entry & exit procedure In Microbial limit test and Biosafety

sop for Gram Staining of Bacteria in Microbiology Laboratory

sop for Monitoring of Compressed Air/gases for microbiological analysis

sop for BET (Bacterial Endotoxin) test in Microbiology

sop for receipt storage and Determining the population of Biological indicators

sop for qualification of analyst microbiologist

sop for Bioburden test of Packing materials in Microbiology Laboratory

sop for microbiological assay of erythromycin antibiotic

sop for liquid particle counter

sop for operation and calibration of digital zone reader

sop for monitoring of ultraviolet efficiency LAF and pass box

microbiological assay of cyanocobalamin or vitamin B12

gowning procedure for microbiological testing area

swab testing of various surfaces for bioburden determination

sop for endotoxin challenge test

Hold time study protocol for sterilized media

sop for personnel Qualification protocol for aseptic area

sop for sampling and testing of drain water

Sop for Operation of Airborne Particle Counter

sop for Validation protocol of steam sterilizer autoclave

sop for pathogen detection from drain point

Sop for Analysis of Raw water Purified water water for injection and pure steam water

sop for preservatives efficacy test

sop for collection and preservation of in house isolated microorganisms

sop for Operation Calibration and Maintenance of Micropipette

sop for microbiological testing of water

sop for depyrogenation of apparatus

sop for fertility test growth promotion test of media

sop for Operation and cleaning of moist heat sterilizer

sop for monitoring by active air sampler

sop for swab sampling and testing for clean rooms in production area

sop for monitoring in microbiology laboratory

sop for Fumigation of aseptic area and microbiology lab

sop for monitoring of personnel in aseptic area

sop for maintenance of cultures

sop for Operation and cleaning of laminar bench

sop for monitoring of pure steam

sop for entry and exit procedure to m.l.t and b.e.t room

sop for storage of and use of media

sop for disposal of microbiological media and cleaning of microbiological glassware