sop for Sterility failure investigation

1 OBJECTIVE

Investigation on sterility failure is required to find out the root cause, and to take the appropriate actions for future analysis.

2 SCOPE

This procedure is applicable to find the cause and take preventive action in case of sterility failure

detected at abc company

3 RESPONSIBILITY

Microbiologist.

4 ACCOUNTABILITY

Head – Q. C

5 ABBREVIATIONS

SOP : Standard Operating Procedure

Q .A : Quality Assurance

Q. C : Quality Control

LAF : Laminar air flow

NO. : Number

CFU : Colony forming units

6 PROCEDURE

If evidence of microbial growth is found during observation of incubated tube of batch or the batch

Tested Does not meet the requirement of sterility test. The reason for positive result shall be investigated as per the Following.

1- Laboratory investigation

2- Production & process investigation

LABORATORY INVESTIGATION:

6.1 Identification of the organism :

6.1.1. Isolate and Identify the microorganism from the test.

6.1.2 Isolate and Identify the microorganism from the environment monitoring plate of the day exposed under LAF.

6.1.3 Isolate and Identify the microorganism from the personal monitoring plate of the microbiologist performed the test.

6.1.4 If the same micro-organism is identified from the environment monitoring plate of LAF or personal monitoring plates. Then the chances of contamination from the environment or person during performing the test.

6.2 Investigation of laboratory test :

6.2.1 Identify the microbiologist performed the test.

6.2.2 Check the positive and negative control tube of the day.

6.2.3 Review the sampling & testing procedure followed by the microbiologist during the testing of the batch.

6.2.4 Review the material and/or technique used in conducting the sterility test by the

microbiologist.

6.2.5 Review the sampling procedure of the test.

6.2.6 Review the History of the test failure by the particular microbiologist.

6.3. Review of Laboratory data and records:

6.3.1 Check the results of area monitoring taken while performing sterility test.

6.3.2 Check the area cleaning record of the day

6.3.3 Check the plate exposure record of LAF of the day.

6.3.4 Check the personal monitoring record of the microbiologist and personnel working in sterile

area.

6.3.5 Check the sterilization records of the Autoclave used on the day of testing.

6.3.6 Check the calibration and validation records of all equipments used in sterility testing.

6.3.7 Review the sterilization record of the media preparation and filtration assembly used in sterility test of the batch. Also review the sterilization record of dresses, filters and equipments used in sterility testing.

6.4 Repetition of test :

6.4.1 If any abnormality found during investigation of test data or records, the positive results may be by the contamination from environment, person, equipment or procedure. The test is invalid and should be repeated. If no abnormality found then the test should be repeated for sterility failure confirmation.

6.4.2 Test should be repeated by another qualified microbiologist.

6.4.3 Test should be performed with all the precautions as per the SOP

6.4.4 Test should be performed after confirmation of all calibration and validation records.

6.4.5 If no growth is observed in re-test, the batch is passed and OOS is invalid.

6.4.6 If batch is fail in sterility then OOS is confirmed and proper investigation should be conducted

on production side to find out the root cause of sterility failure before the disposition the

batch.

PRODUCTION & PROCESS INVESTIGATION:

6.5 Monitoring of production area environment :

Trend analysis of microorganism in the critical and immediately adjacent areas in the production

department is especially helpful in determining the source of contamination in a sterility failure

investigation. Check the results of microbiological monitoring taken during aseptic operations like

dispensing of raw material, manufacturing of batch and filling of bulk solution. Identify the colony

found during the plate exposure in production area on testing date. Also check the area cleaning record and disinfectant usage record in production area. If colony observed in production area is the same as found in repeat test, there are chances of contamination from environment.

6.6 Monitoring of personnel :

Check the personnel monitoring data of the microbiologist and personnel working in sterile area of

production department. Identify the colony found during the personnel monitoring. If the colony observed during personnel monitoring is the same as found in test, there are chances of contamination from the personnel.

6.7 Product bioburden testing :

Reviw the trend of bioburden testing

a) Bioburden testing from mixing tank and holding tank.

b) Bioburden testing of in-process product samples

6.8 Review of sterilization cycle :

Review the sterilization record of dresses, filters and equipments used in during batch preparation as well as sterilization record of filled bottles.

6.9 Review of production records :

6.9.1 Complete batch and production control records should be reviewed to detect any sign of

failure that could have a bearing on product sterility. The investigation should include

elements such as:

6.9.1 Events that could have impacted on critical zone.

6.9.2 Batch and trending data that indicate whether utility or water system are functioning properly.

For instance records of air quality monitoring could show time at which there was or an

unusually high particle count or high CFU found in water system

6.9.3 Whether construction and maintenance activities could have an adverse impact on sterility of

Product.

6.10 Manufacturing history :

The manufacturing history of a product should be reviewed as a part of investigation. Past

deviations, problems or changes (Process, components, equipment) are among the factors that can provide an indication of the origin of the problem.

Appropriate corrective and preventive actions shall be carried out for any of the above reason which Contributed in sterility failure

6.11 Preparation of report:

Proper report of sterility failure investigation is prepared as the Annexure-2.

6.12 Incase of Market complaint

If there is a complaint against product from market,

6.12.1 Immediately call the party to stop the further distribution of the related batch.

6.12.2 Ask to send samples for sterility test (sample sufficient for 2 analyses) from the complaint source.

6.12.3 At the same time collect one sample bottle of the related batch from Control samples &

test for sterility for verification about the geniuses of the complaint

6.12.4 Review of all the points given above under lab investigation will be done.

6.12.5 Send samples for sterility test to an outside government approved laboratory.

6.12.6 The sterility test will be performed in-house by another qualified microbiologist.

6.12.7 Decision shall be taken on the basis of results of IH sterility testing and outside laboratory

sterility test.

07 FREQUENCY

Whenever sterility test failed

08 ENCLOSURES

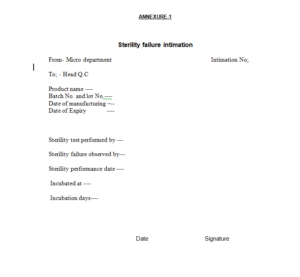

ANNEXURE -1 Sterility failure intimation

ANNEXURE -2 Sterility failure investigation Report

ANNEXURE- 3 Change History Log Format

ANNEXURE-2

Sterility failure investigation report

1– Batch Details

| Product Name | Batch # | ||

| Date of Manufacturing | Filling Room # | ||

| Product Code (if any) | Filling Machine | ||

| Terminally sterilized | Autoclaved lot No. |

2- Sterility Test Details

| Date | Name of Microbiologist | ||

| Time of test performed | Number of

Test performed at same time |

||

| Validated test method | Tested to

Specification |

||

| Date of results | Test session

results |

With positive growth—

With positive growth— |

|

| Positive control

result

|

Negative control

result |

3 Batch review from manufacturing and testing.

| Review of raw

materials used for the manufacture Checked – OK /Not OK |

Batch #

Materials code # Results of tests Checked – OK /Not OK

|

Sign: Date: Review Attached: Yes/No |

| Dispensing of the

raw materials

|

Checked – OK /Not OK

|

Sign:

Date: Review Attached: Yes/No |

| Sterilization cycles

for components /Utensils |

Autoclave#

Cycle# Date Result |

Sign: Date: Review Attached: Yes/No |

Solution Preparation results:

| Distilled water used

for manufacturing |

Date /Time of collection

Date/ Time of performance

Results |

Sign: Date: Review Attached: Yes/No |

| Review Bulk solution

Bio-burden |

Date /Time of collection

Date/ Time of performance

Results |

Sign: Date: Review Attached: Yes/No |

| Review of Filled

Container Bio-burden |

Date /Time of collection

Date/ Time of performance

Results |

Sign:

Date: Review Attached: Yes/No |

| Review of Bacterial

Endotoxins results |

Date /Time of collection

Date/ Time of performance

Results |

Sign: Date: Review Attached: Yes/No |

| Line steaming results | Line #

Date Result

|

Sign:

Date: Review Attached: Yes/No |

| Batch manufacturing Vessel steaming results | Mixing tank #

Date Result |

Sign:

Date: Review Attached: Yes/No |

| Holding tank results | Holding Tank #

Date Result |

Sign:

Date: Review Attached: Yes/No |

| Filtration review | filter #

Date Results |

Sign:

Date: Review Attached: Yes/No |

Environmental monitoring results

| Filling machine room

Viable count -Air |

Exposure time count

Under LAF- Filling Room- Corridor- |

Sign:

Date: Review Attached: Yes/No |

| Filling machine room

Viable count -settle plate |

Exposure time count

Under LAF- Filling Room- Corridor- |

Sign:

Date: Review Attached: Yes/No |

| Filling Machine room

Non-viable particulates count

|

Under LAF-

Filling Room Corridor |

Sign:

Date: Review Attached: Yes/No |

| Manufacturing room

Viable count |

Settle plate –

Air sampling= Surface wall- |

Sign:

Date: Review Attached: Yes/No |

| Manufacturing room

Non- Viable count

|

Count | Sign:

Date: Review Attached: Yes/No |

| Review of Prepared

plate media |

Type of Media

Batch # Expiry Date |

Sign:

Date: Review Attached: Yes/No |

Filling Machine results:

| Setting up

Procedures |

Sign:

Date: Review Attached: Yes/No |

|

| Machine wash water

results |

Machine #

Date Result |

Sign:

Date: Review Attached: Yes/No |

| Error log report | Report

Date Result |

Sign:

Date: Review Attached: Yes/No |

| Filtering review | Sterilization filter #

Date Results |

Sign:

Date: Review Attached: Yes/No |

| Manufacturing

instruction sheet review Interventions Stoppages Reject rate |

Sign:

Date: Review Attached: Yes/No |

|

| Maintenance log

review |

Sign:

Date: Review Attached: Yes/No |

|

| Pressure testing

calibrations |

Sign:

Date: Review Attached: Yes/No |

|

| Differential pressure

excursion review |

Sign:

Date: Review Attached: Yes/No |

|

| Filling Process | Sign:

Date: Review Attached: Yes/No |

|

| All shifts | Sign:

Date: Review Attached: Yes/No |

|

| Sterilization review | Sign:

Date: Review Attached: Yes/No |

|

| Cooling water supply review | Sign:

Date: Review Attached: Yes/No |

|

| Product line integrity | Sign:

Date: Review Attached: Yes/No |

|

| Log Book | Sign:

Date: Review Attached: Yes/No |

Sterile Operator Review

| Name and Number

of Operators & Location of working |

Name

Location |

Sign:

Date: Review Attached: Yes/No |

| Interview of Operator

for any excursion of procedures: |

Name:

Date |

Sign:

Date: Review Attached: Yes/No |

| Training records

Gowning validations |

Name

Training Record |

Sign:

Date: Review Attached: Yes/No |

| Operators Finger

Dabs |

Name

Results |

Sign:

Date: Review Attached: Yes/No |

| Operators personal monitoring record | Name

Results |

Sign:

Date: Review Attached: Yes/No |

QA Review Manufacturing:

| Product Review of

past 12 months of results |

Sign:

Date: Review Attached: Yes/No |

|

| Deviation Reports

Review |

Sign:

Date: Review Attached: Yes/No |

|

| Similar incidents | Sign:

Date: Review Attached: Yes/No |

|

| Change control

history review |

Sign:

Date: Review Attached: Yes/No |

|

| Review of Media run

reports past 12 months |

Sign:

Date: Review Attached: Yes/No |

Sterility Testing Review

| REVIEW AREA | DETAILS | REVIEWED BY |

| Results of known

sterile controls |

Sign:

Date: Review Attached: Yes/No |

|

| Level of false

positives in routine testing (previous 12months) |

Sign:

Date: Review Attached: Yes/No |

|

| Level false positives

in known sterile controls previous 12 months) |

Sign:

Date: Review Attached: Yes/No |

|

| Review of sampling

procedures |

Sign:

Date: Review Attached: Yes/No |

|

| Review of handling

procedures |

Sign:

Date: Review Attached: Yes/No |

|

| Review of swab

method |

Sign:

Date: Review Attached: Yes/No |

|

| Review of certificate

for Sterile test unit |

Sign:

Date: Review Attached: Yes/No |

|

| Review of autoclave

cycle for sterility test equipment |

Sign:

Date: Review Attached: Yes/No |

|

| Media used in

sterility test |

Sign:

Date: Review Attached: Yes/No |

|

| Validation of HEPAs | Sign:

Date: Review Attached: Yes/No |

|

| Validation of

Laminar Flow unit

|

Sign:

Date: Review Attached: Yes/No |

|

| Review of sterility

test session, other batches

|

Sign:

Date: Review Attached: Yes/No |

|

| Training records for

Microbiologist

|

Sign:

Date: Review Attached: Yes/No |

|

| Environment monitoring results for the sterility test room

Viable –Air

|

Air- LAF

Air -Sterility Test room Air -Change room |

Sign:

Date: Review Attached: Yes/No |

| Environment monitoring for the

sterility test room Viable- Settle plate for the test time

|

Settle- LAF-

Settle- Room Settle- Change room |

Sign:

Date: Review Attached: Yes/No |

| Environment monitoring results for the sterility test room

Non- Viable

|

Under- LAF-

Sterility test room- Change room |

Sign:

Date: Review Attached: Yes/No |

| Review of Prepared

plate media |

Type of Media

Batch # Expiry Date |

Sign:

Date: Review Attached: Yes/No |

| Sterility -Microbiologist

Finger Dabs

|

Sign:

Date: Review Attached: Yes/No |

|

| Sterility -Microbiologist

Uniform |

Sign:

Date: Review Attached: Yes/No |

|

| Differential pressure

excursion review

|

Sign:

Date: Review Attached: Yes/No |

|

| Cleaning review

|

|

Sign:

Date: Review Attached: Yes/No |

|

Disinfectants for cleaning |

Sign:

Date: Review Attached: Yes/No |

|

|

Interview of Microbiologist

|

Sign:

Date: Review Attached: Yes/No |

|

| Sterility Log Book | Sign:

Date: Review Attached: Yes/No |

4. Summary of Conclusions found

5. Possible cause/ Root Cause

6. Corrective action

| Task | Responsible | Date Completed |

7 Disposition of batch/Lot

8. Documentation Approval of Investigation

| Prepared by (Microbiologist) | Signature | Date |

| Reviewed by 1( Sr. Microbiologist) | Signature | Date |

| Reviewed by 2 ( Q.C . manager) | Signature | Date |

| Approved by

Quality Assurance Manager |

Signature | Date |

ANNEXURE- 3

CHANGE HISTORY LOG FORMAT

| Rev. No. | Details of changes | Reason for change | Effective Date | Updated By |

|

|

sop for calibration and validation of micro autoclave

sop for Sterility failure investigation

cleaning and operation of discard autoclave

sop for operation of fogger machine

sop for Biological assay of lactic acid bacillus

sop for preparation of culture inoculum

STP for sterility testing of sterile gloves

sop for Operation and calibration of active air sampler

sop for transfer of material for testing and sampling in sterile area

entry & exit procedure in microbiology laboratory

Growth Promotion Test In Microbiology Laboratory

Operation of B.O.D in Microbiology Laboratory

Operation of Horizontal Laminar Air Flow in the microbiology laboratory

Operation and cleaning of Pass Box.

Operation and cleaning of air sampler

Cleaning and Sterilization of Glassware

Analysis of water for microbial load in microbiology lab

Operation and temperature monitoring of Refrigerator

Fumigation of Microbiology Laboratory.

Entry & Exit procedure In Sterility Area

SOP for Microbial analysis of Raw Material Finished Products

SOP for Operation & Calibration of pH meter in Micro Department

SOP for Operation & Calibration of pH meter in Micro Department

SOP Operation and calibration of Hot Air Oven In Microbiology

SOP for operation cleaning & calibration of Digital colony counter

SOP for Operation And Cleaning of Microscope

sop for Media Preparation and Consumption

sop for Receipt Storage and Usage of Culture Media

sop for Cleaning Sanitization And Disinfection In Microbiology

sop for Environmental monitoring of all the Classified area

sop for Handling and Sub culturing of Microbial cultures

sop for Media Growth Promotion Test and various Microbiological test

sop for BOD incubator operation and cleaning

sop sampling of water for microbiological analysis

sop for Disinfectant Efficacy Test

sop for for cleaning and operation of vortex mixture

sop for Temperature & Relative Humidity Monitoring

sop for Operation and Calibration of Heating Block

sop for Sterility Testing of Microbiology

sop for Disposal of Culture Media

sop for Drain point of Microbiology

sop for entry & exit procedure In Microbial limit test and Biosafety

sop for Gram Staining of Bacteria in Microbiology Laboratory

sop for Monitoring of Compressed Air/gases for microbiological analysis

sop for BET (Bacterial Endotoxin) test in Microbiology

sop for receipt storage and Determining the population of Biological indicators

sop for qualification of analyst microbiologist

sop for Bioburden test of Packing materials in Microbiology Laboratory

sop for microbiological assay of erythromycin antibiotic

sop for liquid particle counter

sop for operation and calibration of digital zone reader

sop for monitoring of ultraviolet efficiency LAF and pass box

microbiological assay of cyanocobalamin or vitamin B12

gowning procedure for microbiological testing area

swab testing of various surfaces for bioburden determination

sop for endotoxin challenge test

Hold time study protocol for sterilized media

sop for personnel Qualification protocol for aseptic area

sop for sampling and testing of drain water

Sop for Operation of Airborne Particle Counter

sop for Validation protocol of steam sterilizer autoclave

sop for pathogen detection from drain point

Sop for Analysis of Raw water Purified water water for injection and pure steam water

sop for preservatives efficacy test

sop for collection and preservation of in house isolated microorganisms

sop for Operation Calibration and Maintenance of Micropipette

sop for microbiological testing of water

sop for depyrogenation of apparatus

sop for fertility test growth promotion test of media

sop for Operation and cleaning of moist heat sterilizer

sop for monitoring by active air sampler

sop for swab sampling and testing for clean rooms in production area

sop for monitoring in microbiology laboratory

sop for Fumigation of aseptic area and microbiology lab

sop for monitoring of personnel in aseptic area

sop for maintenance of cultures

sop for Operation and cleaning of laminar bench

sop for monitoring of pure steam

sop for entry and exit procedure to m.l.t and b.e.t room

sop for storage of and use of media

sop for disposal of microbiological media and cleaning of microbiological glassware