Preparation Filtration Usage and Destruction of Disinfectant Solution

1.0. OBJECTIVE :

1.1 To lay down a procedure for Preparation , Filtration ,Usage and destruction of Disinfectant Solution.

2.0 SCOPE :

2.1 This procedure is applicable for Preparation , Filtration ,Usage and destruction of Disinfectant Solution in Injection (Parenteral) at …….

3.0 RESPONSIBILITY :

3.1 Officer/Executive Production

4.0 ACCOUNTABILITY :

4.1 Head of Department

5.0 PROCEDURE :

5.1 DISINFECTANT PREPARATION

5.1.1 Different disinfectant solution to be prepared alternatively for Cleaning/Sanitization of sterile area employees

carrying out this job to be periodically trained.

5.1.2 Select suitable disinfectant from the given chart and make the disinfectant solution as per requirement.

5.1.3 Ensure the cleaning of pressure vessels before the disinfectant preparation.

5.1.4 Ensure the validity of disinfectant before the disinfectant prepration.

| S. No. | Name of Solution | Concentration | Quantity in mL | Quantity WFI in mL | Disnfectant Solution in mL |

| 1. | Acitar in (2% w/v glutaraldehyde , 5% w/v Benzalkonium chloride solution IP) | 5 % | 50 | 950 | 1000 |

| 2. | Totasep in[3% w/v poly (hexamethylenebiguanide) hydrochloride 10% w/v Didecyl dimethyl ammonium Chloride] | 2.5 % | 25 | 975 | 1000 |

| 3. | Silvicide (0.1 % w/v silver nitrate 10 % w/v hydrogen peroxide) | 5 % | 50 | 950 | 1000 |

5.1.5 Prepare 70% Isopropyl Alcohol solution as fast Alcohol base disinfectant for hand gloves.

5.1.6 After preparation filter this solution through 0.2µ Hydrophilic/Hydrophobic filter.

5.1.7 Dispense it in suitable glass/SS container .

5.1.8 Disinfectant shall be rotated as per scheduled mentioned below

| S. No. | Rotation Period | Name of Solution |

| 1. | From date 1st to 10th of month | Acitar (5.0 %V/V) |

| 2. | From date 11st to 20th of month | Totasep (2.5 %V/V ) |

| 3. | From date 21st to end of the month | Silvicide (5.0 %V/V) |

5.2 FILTRATION:

5.2.1 Check Filtration LAF is “ON” and magnehelic Gauge reading is within the limit.

5.2.2 Place the Sterilized membrane under LAF.

5.2.3 Connect the outlet of Disinfectant Filter to the inlet of Disinfectant holding vessel(Filtration vessel).

5.2.4 Connect inlet of Disinfectant Preparation vessel to Nitrogen Supply line.

5.2.5 Open the regulate the Nitrogen pressure through pressure regulator gradually to achieve a pressure of 1.0 to 2.0 Kg/cm².

5.2.6 Allow the solution to pass through the 0.2µ filter and collect solution in Sterilized filtration Vessel.

5.2.7 After complete solution has been filtered close Nitrogen supply valve.

5.2.8 Disconnect all silicone tubes and transfer them to equipment washing area for cleaning .

5.3 USAGE:

5.3.1 For Aseptic area Filtered disinfectant solution is used and prepare only required quantity of disinfectant solution and store in Sterilized container and keep under LAF.

5.3.2 For Non Aseptic area unfiltered disinfectant solution is used and prepares only required quantity.

5.3.3 Destroy the unused quantity at the end of the day, if applicable.

6.0 ABBREVIATION :

| Sr.No. | Abbreviation used | Full form of abbreviation used |

| 1. | SOP | Standard Operating Procedure |

| 2. | WFI | Water For Injection |

| 3. | % | Percentage |

| 4. | IPA | Iso Propyl Alcohol |

| 5. | Ltd | Limited |

| 6. | mL | milliliter |

| 7. | SS | Stainless steel |

| 8. | QA | Quality Assurance |

7.0 ATTACHMENTS (ANNEXES) :

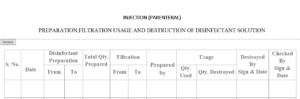

Annex-I : Preparation , Filtration ,Usage and Destruction of Disinfectant Solution

8.0 REFERENCE :

| Sr. No. | Reference Title |

| 1. | In-house |

Annex-I : Preparation , Filtration ,Usage and Destruction of Disinfectant Solution

sop for calibration and validation of micro autoclave

sop for Sterility failure investigation

cleaning and operation of discard autoclave

sop for operation of fogger machine

sop for Biological assay of lactic acid bacillus

sop for preparation of culture inoculum

STP for sterility testing of sterile gloves

sop for Operation and calibration of active air sampler

sop for transfer of material for testing and sampling in sterile area

entry & exit procedure in microbiology laboratory

Growth Promotion Test In Microbiology Laboratory

Operation of B.O.D in Microbiology Laboratory

Operation of Horizontal Laminar Air Flow in the microbiology laboratory

Operation and cleaning of Pass Box.

Operation and cleaning of air sampler

Cleaning and Sterilization of Glassware

Analysis of water for microbial load in microbiology lab

Operation and temperature monitoring of Refrigerator

Fumigation of Microbiology Laboratory.

Entry & Exit procedure In Sterility Area

SOP for Microbial analysis of Raw Material Finished Products

SOP for Operation & Calibration of pH meter in Micro Department

SOP for Operation & Calibration of pH meter in Micro Department

SOP Operation and calibration of Hot Air Oven In Microbiology

SOP for operation cleaning & calibration of Digital colony counter

SOP for Operation And Cleaning of Microscope

sop for Media Preparation and Consumption

sop for Receipt Storage and Usage of Culture Media

sop for Cleaning Sanitization And Disinfection In Microbiology

sop for Environmental monitoring of all the Classified area

sop for Handling and Sub culturing of Microbial cultures

sop for Media Growth Promotion Test and various Microbiological test

sop for BOD incubator operation and cleaning

sop sampling of water for microbiological analysis

sop for Disinfectant Efficacy Test

sop for for cleaning and operation of vortex mixture

sop for Temperature & Relative Humidity Monitoring

sop for Operation and Calibration of Heating Block

sop for Sterility Testing of Microbiology

sop for Disposal of Culture Media

sop for Drain point of Microbiology

sop for entry & exit procedure In Microbial limit test and Biosafety

sop for Gram Staining of Bacteria in Microbiology Laboratory

sop for Monitoring of Compressed Air/gases for microbiological analysis

sop for BET (Bacterial Endotoxin) test in Microbiology

sop for receipt storage and Determining the population of Biological indicators

sop for qualification of analyst microbiologist

sop for Bioburden test of Packing materials in Microbiology Laboratory

sop for microbiological assay of erythromycin antibiotic

sop for liquid particle counter

sop for operation and calibration of digital zone reader

sop for monitoring of ultraviolet efficiency LAF and pass box

microbiological assay of cyanocobalamin or vitamin B12

gowning procedure for microbiological testing area

swab testing of various surfaces for bioburden determination

sop for endotoxin challenge test

Hold time study protocol for sterilized media

sop for personnel Qualification protocol for aseptic area

sop for sampling and testing of drain water

Sop for Operation of Airborne Particle Counter

sop for Validation protocol of steam sterilizer autoclave

sop for pathogen detection from drain point

Sop for Analysis of Raw water Purified water water for injection and pure steam water

sop for preservatives efficacy test

sop for collection and preservation of in house isolated microorganisms

sop for Operation Calibration and Maintenance of Micropipette

sop for microbiological testing of water

sop for depyrogenation of apparatus

sop for fertility test growth promotion test of media

sop for Operation and cleaning of moist heat sterilizer

sop for monitoring by active air sampler

sop for swab sampling and testing for clean rooms in production area

sop for monitoring in microbiology laboratory

sop for Fumigation of aseptic area and microbiology lab

sop for monitoring of personnel in aseptic area

sop for maintenance of cultures

sop for Operation and cleaning of laminar bench

sop for monitoring of pure steam

sop for entry and exit procedure to m.l.t and b.e.t room

sop for storage of and use of media

sop for disposal of microbiological media and cleaning of microbiological glassware

Preparation Filtration Usage and Destruction of Disinfectant Solution