sop for BET (Bacterial Endotoxin) test in Microbiology

1.0 OBJECTIVE

1.1 To down the bacterial endotoxin in WFI & finished pharmaceutical product.

2.0 SCOPE

2.1 This procedure applicable for Bacterial Endotoxin Test in Microbiology Laboratory .

3.0 RESPONSIBILITY

3.1 Microbiologist QC

4.0 ACCOUNTABILITY

4.1 QC Manager

5.0 PROCEDURE

5.1 MATERIALS REQUIRED:

5.1.1 LAL Reagent Water, Control Standard Endotoxin, LAL Reagent, Depyrogenated Micro tips (100 μl &1000 μl), Glass test tube (depyrogenated), Sample to be tested.

5.2 EQUIPMENTS REQUIRED:

5.2.1 Micro pipettes (1000 μl &100 μl ), Vortex Mixer, Heating block

5.3 PROCEDURE FOR TESTING:

5.4 Preparation of Maximum valid dilution:

5.4.1 When the endotoxin limit in the substance or preparation being examined is specified in terms of

weight or units of active drug, the MVD may be calculated by the following formula:

Endotoxin Limit (in EU/ ml /mg) X Potency of product

MVD = ———————————————————————

Labeled sensitivity of lysate in EU /ml (l)

Where Potency =Concentration of the drug in mg / ml or unit /ml

5.4.2 When the endotoxin limit in the sample preparation is specified in terms of volume, the MVD may be

calculated by the following formula.

Endotoxin Limit (EU/ml)

MVD = —————————————————–

Labeled sensitivity of lysate in EU/ml (λ)

5.4.3 Dilute the sample MVD/2 times with LAL water when performing the test at MVD. If performing the test

at MVD/2, dilute the sample MVD/4time with LAL water.

5.5 Preparation of E-Coli Control Standard Endotoxin (CSE):

5.5.1 Reconstitute the CSE with appropriate volume (as stated on certificate) of LAL reagent water vortex

continuous 30 minutes at the interval of 10minutes (When new bottles reconstitute) & vortex vigorously

for five minutes before further dilution

5.6 Preparation of CSE dilution series:

5.6.1 Confirm the labeled sensitivity using at least one vial of each batch/lot of lysate. Prepare a series

of two-fold dilution of the CSE to give concentrations of 2λ, λ, 0.5λ and 0.25λ, where λ is the labeled

sensitivity of the lysate in EU per ml.

5.6.2 Perform the test as given as under Procedure on these four standard concentrations in duplicate or

greater in include negative control consisting of water BET.

5.6.3 Calculate the average of the logarithms of the lowest concentration of endotoxin in each series of

dilutions for which a positive result is found. The antilogarithm of this average gives the estimated

lysate sensitivity, which must be greater than or equal to 0.5λ and less than or equal to 2.0λ.

Confirm the labeled sensitivity of each new batch of lysate prior to use in the test. Test CSE results

are only valid when the positive water and specimen controls are positive at the 2 λ & λ endotoxin concentration.

5.7 Preparation of LAL Reagents:

5.7.1 Test LAL reagent for its sensitivity at the time of receiving. For reconstitution, Collect LAL powder into the bottom of the vial by tapping on a firm surface, unseal and release the vacuum by slowly lifting the

stopper, avoiding touch contamination. The small amount of LAL on the stopper is insignificant.

5.7.2 Rehydrate the reagent with appropriate volume of (as stated on label and certificate) LAL reagent water

by pipetting directly into the vial immediately before use. Cover the vial with an endotoxin free surface or

the inner side of perafilm when not in immediate use. Gently swirl until LAL dissolves into a colorless

solution.

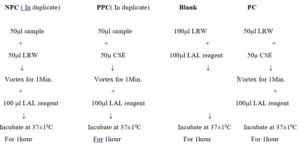

5.8 Test procedure for gel clot:

5.8.1 Each assay should include dilutions of a sample or product, a negative water control, a positive

product control, and either a 2λ water control or a series of two-fold dilutions from an endotoxin

standard which bracket the labeled LAL sensitivity.

5.9 Interpretation of results:

5.9.1 Each tube in the gel-clot method is interpreted as either positive or negative. A positive test is defined as

formation of a firm gel capable of maintaining its integrity when the test tube is inverted 180°C. A negative

test is characterized by the absence of gel or by the formation of a viscous mass, which does not hold

when the tube is inverted. Calculate sample endotoxin concentration by the following formula.

Sample Endotoxin Conc. = Dilution Factor x Sensitivity of λ/ Conc. of Sample (Potency)

5.10 Re-tests:

5.10.1If the positive result is found for one of the test duplicates and a negative result for the other, the test

should be repeated as described above. The results of the retest should be interpreted as for the initial

test.

5.10.2The substance or preparation being examined meets the requirements of the test if the concentration of

endotoxin is less than the endotoxin limit stated in the monograph.

5.11 PRECAUTIONS:

5.11.1Vortex standard Endotoxin for not less than 30 minutes by taping vial to vortex mixture.

5.11.2Vortex all Endotoxin dilution for not less than 1 minute.

5.11.3Do not allow dilution of Endotoxin to stand for more than 10 minutes without re-vortexing

5.11.4Reconstitute Lysate very gently and mix carefully so as to avoid the formation of bubbles.

5.11.5Incubate tube in heating block kept on a stable surface, which do not get vibration, shake or bump.

5.11.6Do not transfer or disturb the tube at any stage of incubation till reading results.

5.11.7Observe result by inverting the tube very gently with constant speed.

5.11.8Observe result only once. Gel is fragile & may break when handled.

5.11.9Start the heating block before around 30 minutes before starting the test to get the temperature stabilize

at the time of incubation.

6.0 ABBREVIATIONS

Abbreviation used Extended Form

SOP : Standard Operating Procedure

QA : Quality Assurance

MB : Microbiology Lab

QC : Quality Control

NPC : Negative Product Control

PPC : Product Positive Control

PC : Positive Control

λ : Sensitivity Of LAL Reagent

EU : Endotoxin unit

MVD : Maximum Valid Dilution

LRW : LAL Reagent Water

LAL : Limulus Amoebocyte Lysate

CSE : Control Standard Endotoxin

sop for calibration and validation of micro autoclave

sop for Sterility failure investigation

cleaning and operation of discard autoclave

sop for operation of fogger machine

sop for Biological assay of lactic acid bacillus

sop for preparation of culture inoculum

STP for sterility testing of sterile gloves

sop for Operation and calibration of active air sampler

sop for transfer of material for testing and sampling in sterile area

entry & exit procedure in microbiology laboratory

Growth Promotion Test In Microbiology Laboratory

Operation of B.O.D in Microbiology Laboratory

Operation of Horizontal Laminar Air Flow in the microbiology laboratory

Operation and cleaning of Pass Box.

Operation and cleaning of air sampler

Cleaning and Sterilization of Glassware

Analysis of water for microbial load in microbiology lab

Operation and temperature monitoring of Refrigerator

Fumigation of Microbiology Laboratory.

Entry & Exit procedure In Sterility Area

SOP for Microbial analysis of Raw Material Finished Products

SOP for Operation & Calibration of pH meter in Micro Department

SOP for Operation & Calibration of pH meter in Micro Department

SOP Operation and calibration of Hot Air Oven In Microbiology

SOP for operation cleaning & calibration of Digital colony counter

SOP for Operation And Cleaning of Microscope

sop for Media Preparation and Consumption

sop for Receipt Storage and Usage of Culture Media

sop for Cleaning Sanitization And Disinfection In Microbiology

sop for Environmental monitoring of all the Classified area

sop for Handling and Sub culturing of Microbial cultures

sop for Media Growth Promotion Test and various Microbiological test

sop for BOD incubator operation and cleaning

sop sampling of water for microbiological analysis

sop for Disinfectant Efficacy Test

sop for for cleaning and operation of vortex mixture

sop for Temperature & Relative Humidity Monitoring

sop for Operation and Calibration of Heating Block

sop for Sterility Testing of Microbiology

sop for Disposal of Culture Media

sop for Drain point of Microbiology

sop for entry & exit procedure In Microbial limit test and Biosafety

sop for Gram Staining of Bacteria in Microbiology Laboratory

sop for Monitoring of Compressed Air/gases for microbiological analysis

sop for BET (Bacterial Endotoxin) test in Microbiology

sop for receipt storage and Determining the population of Biological indicators

sop for qualification of analyst microbiologist

sop for Bioburden test of Packing materials in Microbiology Laboratory

sop for microbiological assay of erythromycin antibiotic

sop for liquid particle counter

sop for operation and calibration of digital zone reader

sop for monitoring of ultraviolet efficiency LAF and pass box

microbiological assay of cyanocobalamin or vitamin B12

gowning procedure for microbiological testing area

swab testing of various surfaces for bioburden determination

sop for endotoxin challenge test

Hold time study protocol for sterilized media

sop for personnel Qualification protocol for aseptic area

sop for sampling and testing of drain water

Sop for Operation of Airborne Particle Counter

sop for Validation protocol of steam sterilizer autoclave

sop for pathogen detection from drain point

Sop for Analysis of Raw water Purified water water for injection and pure steam water

sop for preservatives efficacy test

sop for collection and preservation of in house isolated microorganisms

sop for Operation Calibration and Maintenance of Micropipette

sop for microbiological testing of water

sop for depyrogenation of apparatus

sop for fertility test growth promotion test of media

sop for Operation and cleaning of moist heat sterilizer

sop for monitoring by active air sampler

sop for swab sampling and testing for clean rooms in production area

sop for monitoring in microbiology laboratory

sop for Fumigation of aseptic area and microbiology lab

sop for monitoring of personnel in aseptic area

sop for maintenance of cultures

sop for Operation and cleaning of laminar bench

sop for monitoring of pure steam

sop for entry and exit procedure to m.l.t and b.e.t room

sop for storage of and use of media

sop for disposal of microbiological media and cleaning of microbiological glassware