sop for Bioburden test of Packing materials in Microbiology Laboratory

1.0 OBJECTIVE

1.1 To lay down a procedure for Microbiological Content Test of Packing materials.

2.0 SCOPE

2.1 This procedure applicable for Bioburden test of Packing materials in Microbiology Laboratory

3.0 RESPONSIBILITY

3.1 Officer Microbiologist

3.2 Executive Microbiologist

4.0 ACCOUNTABILITY

4.1 Head –QC

5.0 PROCEDURE

5.1 Requirement

5.1.1 Sterile Normal Saline (0.9%w/v Sod. Chloride Solution)

5.1.2 Sterile Swab sticks which is sterilized in a test tube containing 10 ml Normal saline

5.1.3 Pre prepared SDA (Sabouraud Dextrose Agar) and SCDA (Soyabean Casein Digest Agar) Media as per SOP

5.2 Methodology

5.2.1 Take the pre-sterilized and pre-incubated settle Petri plates of SCDA (Soyabean Casein Digest agar).

5.2.2 Prepare the 100 ml normal saline in two conical flask and autoclave it.

5.2.3 Take pre sterilize Sabouraud Dextrose Agar plates.

5.2.4 Check the Bio-burden of the Primary packaging materials i.e. Aluminium foils, PVC, PVDC foil.

5.2.5 Select the no. of rolls from the consignment. It should be not less than √N + 1 of the total consignment.

5.3 For Aluminium foils/PVC/PVDC

5.3.1 One circular layer of foil is discarded and in next layer an area of approximately 100 sq. cms shall be examined.

5.3.2 Swab the entire internal surface of the sample with the help of a sterile swab stick which is dipped in sterile normal saline (10ml).

5.3.3 Streak the swab on the surface of sterile SDA and SCDA plates (Duplicate Plates).

5.3.4 Incubate the SDA plates at 20 – 25ºC for 5 days and SCDA plates at 30 – 35ºC for 5 days.

5.3.5 After the completion of incubation period record the results.

5.3.6 If the results are not within the specified limit, further sampled some more rolls and analyze.

5.3.7 If again results are not within the specified limit reject the consignment. If one or two rolls are showing

results beyond the specification reject the individual rolls.

5.4 For Bottles or container

5.4.1 Take one piece of container or bottle with cap and transfer 10ml of saline solution to the container or bottle.

5.4.2 Shake the flask/container or bottle gently to recover the bio-burden into the saline for 8 to 10 min.

5.4.3 Perform the testing by Pour plate method.

5.4.4 Transfer 1ml solution in the surface of the SDA and SCDA plates (Duplicate Plates).

5.4.5 Incubate the SDA plates at 20 – 25ºC for 5 days and SCDA plates at 30 – 35ºC for 5 days.

5.4.6 After the completion of incubation period record the results.

5.4.7 If the results are not within the specified limit, further sampled some more bottles and analyze.

5.4.8 If again results are not within the specified limit reject the consignment.

5.5 For Dropper Assembly/Caps

5.5.1 Fill the dropper assembly with sterile normal saline and collect in a sterile conical flask.

5.5.2 In case of PP caps fill the sampled caps with 1-2ml of sterile normal saline and collect the solution in a sterile conical flask.

5.5.3 Transfer 1ml solution in the surface of the SDA and SCDA plates (Duplicate Plates).

5.5.4 Incubate the SDA plates at 20 – 25ºC for 5 days and SCDA plates at 30 – 35ºC for 5 days.

5.5.5 After the completion of incubation period record the results.

5.5.6 If the results are not within the specified limit, further sampled some more bottles and analyze.

5.5.7 If again results are not within the specified limit reject the consignment.

5.5.8 Carry out the Microbiological bio burden analysis of primary Packaging Material for every consignments of approved material.

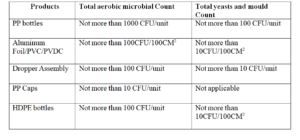

5.6 Limit Acceptance criteria

6.0 ABBREVIATIONS

QCM : Quality Control Microbiology

SOP : Standard Operating Procedure

QA : Quality Assurance

GTP : General Testing Procedure

QC : Quality Control

CFU : Colony Forming Units

sop for calibration and validation of micro autoclave

sop for Sterility failure investigation

cleaning and operation of discard autoclave

sop for operation of fogger machine

sop for Biological assay of lactic acid bacillus

sop for preparation of culture inoculum

STP for sterility testing of sterile gloves

sop for Operation and calibration of active air sampler

sop for transfer of material for testing and sampling in sterile area

entry & exit procedure in microbiology laboratory

Growth Promotion Test In Microbiology Laboratory

Operation of B.O.D in Microbiology Laboratory

Operation of Horizontal Laminar Air Flow in the microbiology laboratory

Operation and cleaning of Pass Box.

Operation and cleaning of air sampler

Cleaning and Sterilization of Glassware

Analysis of water for microbial load in microbiology lab

Operation and temperature monitoring of Refrigerator

Fumigation of Microbiology Laboratory.

Entry & Exit procedure In Sterility Area

SOP for Microbial analysis of Raw Material Finished Products

SOP for Operation & Calibration of pH meter in Micro Department

SOP for Operation & Calibration of pH meter in Micro Department

SOP Operation and calibration of Hot Air Oven In Microbiology

SOP for operation cleaning & calibration of Digital colony counter

SOP for Operation And Cleaning of Microscope

sop for Media Preparation and Consumption

sop for Receipt Storage and Usage of Culture Media

sop for Cleaning Sanitization And Disinfection In Microbiology

sop for Environmental monitoring of all the Classified area

sop for Handling and Sub culturing of Microbial cultures

sop for Media Growth Promotion Test and various Microbiological test

sop for BOD incubator operation and cleaning

sop sampling of water for microbiological analysis

sop for Disinfectant Efficacy Test

sop for for cleaning and operation of vortex mixture

sop for Temperature & Relative Humidity Monitoring

sop for Operation and Calibration of Heating Block

sop for Sterility Testing of Microbiology

sop for Disposal of Culture Media

sop for Drain point of Microbiology

sop for entry & exit procedure In Microbial limit test and Biosafety

sop for Gram Staining of Bacteria in Microbiology Laboratory

sop for Monitoring of Compressed Air/gases for microbiological analysis

sop for BET (Bacterial Endotoxin) test in Microbiology

sop for receipt storage and Determining the population of Biological indicators

sop for qualification of analyst microbiologist

sop for Bioburden test of Packing materials in Microbiology Laboratory

sop for microbiological assay of erythromycin antibiotic

sop for liquid particle counter

sop for operation and calibration of digital zone reader

sop for monitoring of ultraviolet efficiency LAF and pass box

microbiological assay of cyanocobalamin or vitamin B12

gowning procedure for microbiological testing area

swab testing of various surfaces for bioburden determination

sop for endotoxin challenge test

Hold time study protocol for sterilized media

sop for personnel Qualification protocol for aseptic area

sop for sampling and testing of drain water

Sop for Operation of Airborne Particle Counter

sop for Validation protocol of steam sterilizer autoclave

sop for pathogen detection from drain point

Sop for Analysis of Raw water Purified water water for injection and pure steam water

sop for preservatives efficacy test

sop for collection and preservation of in house isolated microorganisms

sop for Operation Calibration and Maintenance of Micropipette

sop for microbiological testing of water

sop for depyrogenation of apparatus

sop for fertility test growth promotion test of media

sop for Operation and cleaning of moist heat sterilizer

sop for monitoring by active air sampler

sop for swab sampling and testing for clean rooms in production area

sop for monitoring in microbiology laboratory

sop for Fumigation of aseptic area and microbiology lab

sop for monitoring of personnel in aseptic area

sop for maintenance of cultures

sop for Operation and cleaning of laminar bench

sop for monitoring of pure steam

sop for entry and exit procedure to m.l.t and b.e.t room

sop for storage of and use of media

sop for disposal of microbiological media and cleaning of microbiological glassware

very good documents