sop for maintenance of cultures

1.0 OBJECTIVE

To lay down a procedure for maintaining of bacterial cultures.

2.0 RESPONSIBILTY

Microbiologist / Executive.

3.0 ACCOUNTABILITY

Head – Quality Control

3.0 PROCEDURE

4.1 Bacterial cultures are very sensitive and if not sub-cultured they can change their morphological & biochemical characteristics.

Sub-culturing or periodic transfer is a very delicate technique which has to be carried out by avoiding chances of contamination.

4.3 Prepare the media as mentioned in SOP

4.2 Prepare slants in clean 18 mm diameter rimless test tubes and pre-incubate for 48 hrs at 30-35C to check any contamination.

4.3 Boil the media till get completely dissolve. Cool to about 42 – 45°C and adjust the required pH . Fill each test tube with

about 9 to 10ml of the medium & plug the tubes with non absorbent cotton & sterilize by autoclaving.

4.4 After autoclaving, prepare the solutions by slanting the test tubes to desirable angle.

4.5 After the medium get solidified, keep the prepared slants into the incubators (37°C for 48 hrs.)for pre incubation.

4.8 Prior to sub culturing incubation is necessary because to check for the contamination of slants

occurs in process.

4.9 After incubation, clean the exterior surface of test tube with IPA 70% solution.

4.10 Mark each test tube with the name of organism & date of subculture.

4.11 At every passage from mother culture check the Gram character and morphology of the culture. In any case the passage from mother culture shall not exceed 5.

4.12 Subculture should be done in the of Laminar flow clean air station & in between the two gas burners to avoid the chances of cross contamination.

Take a loop full of culture from previous stock cultures or mother culture which ever is applicable, and inoculate in freshly prepared sterile slant

4.13 Inoculate each organism in two slants ( prepare two slants of each organism). After inoculating ,incubate all the tubes at required

temperature(i.e. 30-35°C for bacteria and 20-25°C for fungus).

4.13 After incubation check the cultures visibly for any contamination.

4.15 Mark the Newly prepared lot of cultures tubes as WORKING CULTURES and one as STOCK

CULTURE.

4.16 After observing the growth, keep the newly prepared cultured tubes in clean double plain

polythene bags and preserved the tubes in the refrigerator at 2 – 8 °C.

4.17 Prepare new slants from the STOCK CULTURE of previous month ( at each month ,as a new passage)

and should proceed from more than four passage.

4.18 After completion of two passages from a single STOCK CULTURE, take the passage from MOTHER

CULTURE slant, proceed for the next passage , by preparing STOCK CULTURE and WORKING

CULTURE.

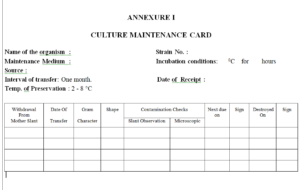

4.19 Enter the date of sub-culturing and passage number in the format as mentioned in Annexure I for sub-

culturing of micro-organism.

4.20 After every one year procure the new culture from any national recognized institution with certificate for

authenticity of the cultures.

4.21 The working cultures shall be used for preparing suspensions for positive control; for Growth Promotion

test etc.

4.22 The STOCK CULTURE shall be used only for sub culturing.

4.23 After one month when the new cultures are ready for use destroy the old cultures.

5.0 DISPOSAL OF CULTURES :

5.1 Aseptically pipette 10ml of disinfectant solution in the culture tubes.

5.2 Sterilise at 121 °C for 20 mins.

5.3 After sterilization collect the media in the double polybag, pour sufficient disinfectant solution and tie it

properly. Dispose this bag in Incinerator.

6.0 MEDIA USED FOR PREPARING SLANTS :

1. For Bacteria : Soyabean Casein digest Agar.

2. For Fungi : Sabaroud Dextrose Agar.

7.0 ABBREVIATIONS : NIL

8.0 REFERENCE

Recommendations by culture supplier.

9.0 ANNEXURE : Annexure I

sop for calibration and validation of micro autoclave

sop for Sterility failure investigation

cleaning and operation of discard autoclave

sop for operation of fogger machine

sop for Biological assay of lactic acid bacillus

sop for preparation of culture inoculum

STP for sterility testing of sterile gloves

sop for Operation and calibration of active air sampler

sop for transfer of material for testing and sampling in sterile area

entry & exit procedure in microbiology laboratory

Growth Promotion Test In Microbiology Laboratory

Operation of B.O.D in Microbiology Laboratory

Operation of Horizontal Laminar Air Flow in the microbiology laboratory

Operation and cleaning of Pass Box.

Operation and cleaning of air sampler

Cleaning and Sterilization of Glassware

Analysis of water for microbial load in microbiology lab

Operation and temperature monitoring of Refrigerator

Fumigation of Microbiology Laboratory.

Entry & Exit procedure In Sterility Area

SOP for Microbial analysis of Raw Material Finished Products

SOP for Operation & Calibration of pH meter in Micro Department

SOP for Operation & Calibration of pH meter in Micro Department

SOP Operation and calibration of Hot Air Oven In Microbiology

SOP for operation cleaning & calibration of Digital colony counter

SOP for Operation And Cleaning of Microscope

sop for Media Preparation and Consumption

sop for Receipt Storage and Usage of Culture Media

sop for Cleaning Sanitization And Disinfection In Microbiology

sop for Environmental monitoring of all the Classified area

sop for Handling and Sub culturing of Microbial cultures

sop for Media Growth Promotion Test and various Microbiological test

sop for BOD incubator operation and cleaning

sop sampling of water for microbiological analysis

sop for Disinfectant Efficacy Test

sop for for cleaning and operation of vortex mixture

sop for Temperature & Relative Humidity Monitoring

sop for Operation and Calibration of Heating Block

sop for Sterility Testing of Microbiology

sop for Disposal of Culture Media

sop for Drain point of Microbiology

sop for entry & exit procedure In Microbial limit test and Biosafety

sop for Gram Staining of Bacteria in Microbiology Laboratory

sop for Monitoring of Compressed Air/gases for microbiological analysis

sop for BET (Bacterial Endotoxin) test in Microbiology

sop for receipt storage and Determining the population of Biological indicators

sop for qualification of analyst microbiologist

sop for Bioburden test of Packing materials in Microbiology Laboratory

sop for microbiological assay of erythromycin antibiotic

sop for liquid particle counter

sop for operation and calibration of digital zone reader

sop for monitoring of ultraviolet efficiency LAF and pass box

microbiological assay of cyanocobalamin or vitamin B12

gowning procedure for microbiological testing area

swab testing of various surfaces for bioburden determination

sop for endotoxin challenge test

Hold time study protocol for sterilized media

sop for personnel Qualification protocol for aseptic area

sop for sampling and testing of drain water

Sop for Operation of Airborne Particle Counter

sop for Validation protocol of steam sterilizer autoclave

sop for pathogen detection from drain point

Sop for Analysis of Raw water Purified water water for injection and pure steam water

sop for preservatives efficacy test

sop for collection and preservation of in house isolated microorganisms

sop for Operation Calibration and Maintenance of Micropipette

sop for microbiological testing of water

sop for depyrogenation of apparatus

sop for fertility test growth promotion test of media

sop for Operation and cleaning of moist heat sterilizer

sop for monitoring by active air sampler

sop for swab sampling and testing for clean rooms in production area

sop for monitoring in microbiology laboratory

sop for Fumigation of aseptic area and microbiology lab

sop for monitoring of personnel in aseptic area

sop for maintenance of cultures

sop for Operation and cleaning of laminar bench

sop for monitoring of pure steam

sop for entry and exit procedure to m.l.t and b.e.t room

sop for storage of and use of media

sop for disposal of microbiological media and cleaning of microbiological glassware