sop for Operation of Air Compressor and Air Dryer

1.0 OBJECTIVE :

1.1 To lay down a procedure for operation of Air compressor

2.0. SCOPE :

2.1 procedure is applicable to the operation of Air compressor situated at Pharma Dekho

3.0. RESPONSIBILITY :

3.1 Machine Operator shall be responsible for monitoring the operation of Air Compressor

3.2 Engineer shall be responsible for Corrective action in case of any deviation and Verifying the

Performance parameters as per acceptance criteria.

4.0. ACCOUNTABILITY :

4.1 Engineering Head shall be accountable for compliance of SOP.

5.0. PROCEDURE :

5.1 PRE -OPERATION CHECK LIST OPERATION OF AIR COMPRESSOR

5.1.1 Check the position of safety switches.

5.1.2 Drain the condensed water from Air receiver

5.1.3 Check the tightness of “V” belts.

5.1.4 Check oil level in compressor & coolant level in Air Heat exchanger.

5.1.5 Check the discharge valve is close

5.2 STARTING PROCEDURE OPERATION OF AIR COMPRESSOR

5.2.1 Unload compressor by the unloader.

5.2.2 Switch on the main switch & push green ‘START’ button of cooling tower.

5.2.3 Switch on the main switch & push green ‘START’ button of air compressor

5.2.4 Manually operate Force Feed Lubricator and check the compressor oil level through the sight glass

5.2.5 Start the motor of the compressor by using the start button, which is on the switchboard.

5.2.6 Observe that the compressor is running on unload mode for 1 -2 minutes.

5.2.7 Load the compressor.

5.2.8 Check the following during running stage

5.2.9 Check electric motor shall be over-heated.

5.2.10 Check and ensure that the auto condensate drain is working properly of receiver and after cooler.

5.2.11 Level of coolant level in indicator shall be checked.

5.2.12 Check any abnormal noise.

5.3 STARTING PROCEDURE OPERATION OF AIR DRYER:-

5.3.1 Select the Dryer for operation

5.3.2 Switch “ON” the dryer.

5.3.3 Open the inlet valve slowly.

5.3.4 Avoid any sudden variation in pressure.

5.3.5 Slowly open the upstream valve and check the circulation of air.

5.3.6 Check the inlet flow and machine utilization.

5.3.7 Check the purging and Regeneration cycle in Heatless Dryer or check given line indication in refrigerant Dryer

5.4 STOPPING PROCEDURE OPERATION OF AIR COMPRESSOR

5.4.1 Closed discharge valve.

5.4.2 Unload compressor using manual operated hand wheel on unloaders and allow compressor to run for around 5 minutes in unload mode before stopping.’

5.4.3 Switch off the power supply to the unit and observe that the compressor stops.

5.4.4 Stop the water circulation pump.

5.4.5 Record all the operations.

5.4.6 Change the inlet3/2 way valve to bypass position.

5.4.7 Leave the dryer controller in switched “ON” condition.

5.4.8 Ensure the 2 tower pressure gauge indicates 0 kg/cm2′.

5.4.9 Switch “OFF” the controller.

5.5 STOPPING PROCEDURE OF AIR DRYER:-

5.5.1 Close the inlet valve.

5.5.2 Leave the dryer controller in switched “ON” condition.

5.5.3 Ensure the pressure gauge indicates 0 kg/cm2 (in Heatless)

5.5.4 Switch “OFF” the controller.

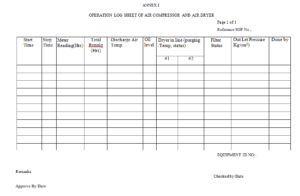

5.5.5 Take the reading of four hour of operation of compressor and air dryer as par annexure -I.

6.0. ABBREVIATION :

| Sr. No. | Abbreviation used | Full form of abbreviation used |

| 1. | SOP | Standard operating procedure |

| 2. | EM | Engineering & maintenance |

7.0 ATTACHMENTS (ANNEXES) :

Annex-I: Operation log sheet of Air Compressor and Air Dryer

8.0. REFERENCE

In House

sop for Execution of Preventive Maintenance

Preparation of Sodium Hydroxide Solution

sop for water cooled chiller operation

cleaning and preventive maintenance of LAF and RLAF

sop for replacement of water system filters

cleaning and preventive maintenance of insectocutor

sop for operation of preventive maintenance

sop for material receiving and consumption record

sop for Preventive maintenance of bottle washing machine

sop for Replacement of Battery of Electronic Devices

sop for Preparation of R.O. Antiscalant Solution

Preventive Maintenance of Rapid Cooling Steam Sterilizer

Preventive Maintenance of Rapid cooling steam Generator

sop for Preventive Maintenance of Dust Collector

sop for Replacement of HVAC filters

SOP for Battery Backup in Mobile Laminar Air Flow Trolley

sop for Replacement of Tube lights

sop for Replacement of UV light of purified water plant

sop for Cleaning of soft water storage tank and RO feed tank

sop for Preparation of Sodium hydroxide Solution

sop for Operation and regeneration of softener plant

Procedure Of Issuance Of material from Engineering Store

sop for Preventive Maintenance of Filter Press

sop for Preventive Maintenance of Sugar Transfer System

sop for Preventive Maintenance of Shrink Sleeve Machine

sop for Preventive Maintenance of ROPP Cap Elevator

sop for Preventive Maintenance of Liquid Transfer Pumps

sop for Preventive Maintenance of Liquid Tanks

Preventive Maintenance of Strip De-Foiling Machine

sop for Preventive Maintenance of Colloidal Mill

sop for Preventive Maintenance of Packing Collator Belt

sop for Checking light intensity

sop for Operation of Fire- Extinguisher

sop for Passivation of WFI Distribution Loop

sop for Analysis of Effluent Treatment Plant Water

sop for Methodology to Dispose ETP Sludge

sop for Action Plan In Case Of Electrical Power Failure

sop for Colour Coding of Piping and Accessories of Utilities

sop for Disposal of Engineering Waste

Filter Cleaning of HVAC System RLAF & LAF

Procedure for Calibration of Magnehelic Gauge

Procedure for Calibration of Vacuum Gauge

Procedure for Calibration of Pressure Gauge

sop for Procedure for Calibration of Temperature Controller

sop for Preventive Maintenance of Infrared Dryer Umbrella Type

sop for Preventive Maintenance of Battery stacker

sop for Preventive Maintenance of Lift

sop for Preventive Maintenance of Vacuum Cleaner

sop for Preventive Maintenance of laminar air flow unit

sop for Preventive Maintenance of Lozenges Manufacturing Line

sop for Preventive Maintenance of Garment Washing Machine

sop for Preventive Maintenance of Multi Column Distillation Plant

sop for Preventive Maintenance of Steam Sterilizer Autoclave

sop for Preventive Maintenance of Pure steam Generator

sop for Preventive maintenance of Depyrogenating Tunnel

sop for Preventive Maintenance of vial sealing machine

sop for preventive maintenance of Powder Filling and Rubber Stoppering machine

sop for Preventive Maintenance of Vial Washing Machine

sop for Preventive Maintenance of Inspection Table

sop for Preventive Maintenance of Hi-Cart

sop for Preventive Maintenance of Turn table

sop for Preventive Maintenance of sticker labeling machine

sop for Preventive Maintenance of Liquid Filling and Sealing Machine

sop for Preventive Maintenance of Linear Bottle Washing Machine

sop for Preventive Maintenance of De-Foiling Machine

sop for Preventive Maintenance of Strip Packing Machine

sop for Preventive Maintenance of Blister Packing Machine

sop for Preventive Maintenance of Capsule Polishing and Sorting Machine

sop for Preventive Maintenance of Capsule Filling Machine

sop for Preventive maintenance of Auto Coater

sop for Preventive Maintenance of Compression Machine

sop for preventive maintenance of packing conveyor belt

sop for Preventive Maintenance of Sifter Cum Multi mill

sop for Preventive Maintenance of Rapid Mixer Granulator

sop for Preventive Maintenance Of Fluid Bed Dryer

sop for Preventive Maintenance of Octagonal Blender

sop for Preventive Maintenance of Lifting and Positioning Device

sop for Preventive Maintenance of Paste Preparation vessel

sop for preventive maintenance of Vibro-Sifter

sop for preventive maintenance of air curtain

sop for preventive maintenance of air handling units

Preventive Maintenance of Diesel Generator

sop for Preventive Maintenance of cooling towers

sop for Preventive Maintenance of Boiler

sop for Preventive Maintenance of Air Compressor

sop for Preventive Maintenance of Chilling Plant

sop for Preventive Maintenance of Transformers

sop for Preventive maintenance of Purified Water System

sop for Break Down maintenance of Machine and Work Requisition