sop for Validation protocol of steam sterilizer autoclave

TABLE OF CONTENTS

Sr. No. Title Page No.

1 PROTOCOL APPROVAL SHEET…………………………..……………..

2 OBJECTIVE…………………………………………………………………..

3 SCOPE…………………………………………………………………..……

4 RESPONSIBILITY……………………………………………………..…….

5 EQUIPMENT DESCRIPTION………………………………………………

6 REQUIREMENT……………………………………………………………..

7 LOAD PATTERN FOR VALIDATION OF AUTICLAVE………………….

8 VALIDATION METHODOLOGY FOR AUTOCLAVE………..……..……

9 SET PARAMETER…………………………………………..…………..….

10 REVALIDATION CRITERIA…………………………………………………

11 FREQUENCY OF VALIDATION……………………………………………

12 DEFINITION…………………………………………………………………..

13 REFERENCE…………………………………………………………………

14 DOCUMENTS……………………………………………………….……….

15 ABBREVIATIONS…………………………………………………………….

1.0 PROTOCOL APPROVAL

This Validation Protocol has been prepared and Reviewed and Approved by following:

DEPARTMENT NAME DESIGNATION SIGNATURE DATE

PREPARED BY

Executive – QA

CHECKED BY

Head

Quality Control

APPROVED BY

Head

Quality Assurance

2.0 OBJECTIVE:

The objective of this protocol is designed to establish sufficient data to assure that the Autoclave Supplied by

M/s. ABC equipment is suitable for sterilizing the loads. In addition, this validation protocol is intended to

assure the sterility of the items, when the equipment is operated in accordance with the established standard

operating procedure to maintain reliability and repeatability.

3.0 SCOPE:

This protocol is applicable For Vertical Autoclave, which is installed in Quality Control deptt. Microbiology section

4.0 RESPONSIBILITY:

| Department | Responsibilities |

| Microbiology | Development of Validation protocol and assembling of data into a final report.

Placing of Biological indicator & chemical indicator(strips) Collection & analysis of Biological indicator |

| Quality Control | Review of this protocol. |

| Quality Assurance | Review and Approval of protocol and of the final report. |

5.0 EQUIPMENT DESCRIPTION:

5.1 Autoclave Ist

Name of the Equipment : Steam Sterilizer (Autoclave)

Make : ABC

Equipment I D No. :

Equipment Location. : Autoclave (Microbiology Department)

5.2 Autoclave IInd

Name of the Equipment : Steam Sterilizer (Autoclave)

Make : ABC

Equipment I D No. :

Equipment Location. : Autoclave (Microbiology Department)

5.3 USE OF EQUIPMENT:

5.3.1 The Autoclave is used for decontamination of culture dilution tubes & slants, Environmental monitoring plates & tubes,

water testing plates & tubes, Raw material MLT plates & tubes, Finished product MLT plates & tubes, disinfectant testing

media tubes, used micropipette tips, positive and negative cultures plates and tubes, Environmental isolates plates & tubes

at 121° to 124°C for decontamination of the media is accomplished by heat transfer from steam to media.

6.0 REQUIREMENT:

6.1 In order to efficiently conduct validation of an Autoclave, the following requirements must be fulfilled

6.1.1 Calibrated Data logger with PT-100 sensors.

6.1.2 Biological Indicator for Pours & Liquid Load (106 spores of Bacillus stearothermophilus in

strips.

6.1.3 Culture media used for validation purpose

6.1.4 All instruments used for validation must be calibrated.

7.0 LOAD PATTERN FOR VALIDATION OF AUTOCLAVE

7.1 Empty Chamber Heat distribution studies with temperature mapping probe at different locations of the sterilizer chamber.

7.2 Loaded chamber heat Distribution & penetration studies for each sterilization load of fixed loading pattern at 121ºC.

7.3 Porous Load (Heat Penetration Studies for Sterilization of Glass wares, Accessories hand gloves etc.)

7.4 Liquid Load (Heat Penetration Studies for Sterilization of media etc.)

8.0 VALIDATION METHODOLOGY FOR AUTOCLAVE

8.1 Heat distribution studies (Empty Lode)

8.1.1 Objective:

8.1.1.1 Objective of this test is to ensure that, the steam sterilizer is capable of attaining a temperature of 1210C during the

sterilization hold period with steam pressure of 1.1 to 1.2 kg/cm2.

8.1.1.2 Temperature spread within the range of 1210C to 1240C during sterilization cycle will demonstrate the uniform

heat distribution within the chamber.

8.1.2 Procedure

8.1.2.1 Record the set parameter for the sterilization cycle to be operated during the test for empty chamber heat distribution study.

8.1.2.2 Pass minimum 8 no. Temperature mapping probe into chamber through the port of the sterilizer. Seal the port with silicone sealant so

that steam leakage does not take place. Suspend the probes in the chamber in different position so that probes do not touch any metallic.

Record the position of the probes in a respective schematic form.

8.1.2.3 Connect the probes to a suitable data logger, which can scan and print the actual temperature observed at different locations with respect to time.

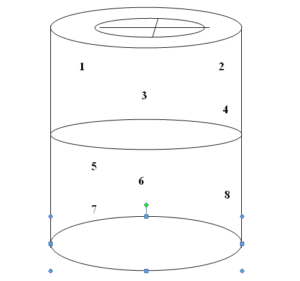

Figure 1.0 – Schematic diagram for Probe Location for Empty Cycle (1-8 are the locations for probe)

8.1.2.4 Operate the autoclave as per SOP and also start the data logger to record actual temperature within the sterilization chamber with respect to time.

8.1.2.5 When the sterilization cycle completes, Download the data-analysis and printing. Record the temperatures observed at different locations.

8.1.2.6 If the empty chamber heat distribution study is acceptable perform three consecutive runs to demonstrate cycle and sterilizer reproducibility.

8.1.3 Acceptance Criteria

8.1.3.1 Throughout the well time all temperature measured in the chamber do not fluctuate by more than 10C

8.1.3.2 The minimum accumulated F0 value should be more than biological F0 value for the Biological indicator strips exposed to the bio-challenge studies.

8.2 Loaded Chamber Heat Distribution & Penetration Studies Along with chemical & Biological Indicator (Porous Load & Liquid Load)

8.2.1 Objective

8.2.1.1 Objective of this test is to ensure that, the steam is sufficiently penetrating into the innermost portions of the load subjected for sterilization

to achieve desired Fo Value during the complete sterilization hold period.

8.2.1.2 If the minimum Fo Value is not achieved throughout the cycle, load configuration or size of the load has to be reviewed and cycle to be repeated.

8.2.1.3 Temperature spread within the range of 1210C to 1240C during sterilization hold period indicate that, uniform heating process which is

achieved in the empty chamber heat distribution study is not affected by load.

8.2.1.4 There could be the possibility of lag period for attaining 1210C during heat penetration runs as the probes are placed

deep into the load. But if minimum Fo Value is achieved at each probe, there is no need to consider for lag period. But if minimum Fo Value is not achieved at each probe, then cycle time will have to be increased so as to achieve minimum Fo Value.

8.2.1.5 The location where minimum Fo Value is observed during the sterilization cycle will be considered as cold spot.

8.2.2 Procedure

8.2.2.1 Record the set parameter for the sterilization cycle to be operated during the test for loaded chamber heat penetration study in the Annexure.

8.2.2.2 Pass minimum 8 no. Temperature mapping probes into chamber through the port provided. Seal the port with silicone sealant so that steam leakage does not take place. Place the probes inside the load components, which are supported to be most difficult points for steam penetration, also place biological indicator along with each temperature mapping probe during the last cycle of media discard. Record the position of the probes and biological indicators in a representative schematic form.

8.2.2.3 Connect the probes to a suitable data logger, which can scan and print the actual temperature with respect to time.

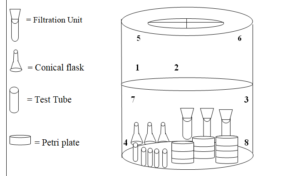

Figure 2.0 – Schematic diagram for Probe Location along with Biological Indicator media sterilization loaded cycle

Figure 3.0 – Schematic Location of glassware at the time of sterilization

8.2.2.4 Operate the steam Sterilizer as per SOP and also start the data logger to record the actual temperatures within the sterilization

chamber with respect to time.

8.2.2.5 When the sterilization cycle completes, Record the temperatures observed at different locations. Aseptically collect the

exposed biological indicators and send the indicators to microbiology lab for further incubation and observed the results.

8.2.2.6 If the load penetration study is acceptable perform three consecutive runs to demonstrate cycle and sterilizer reproducibility.

Compile the data generated during the qualification test for complete evaluation of the system.

8.2.3 Acceptance Criteria

8.2.3.1 Throughout the dwell time all temperature measured in the chamber do not fluctuate by more than 10C.

8.2.3.2 The calculated minimum F0 value should be more than biological F0 value for the Biological indicator strips exposed to the bio-challenge studies.

8.2.3.3 No growth should be observed for exposed sterilized indicator & Negative Control (unexposed indicator) in the SCDM.

8.2.3.4 Growth should be observed in the Positive control tube that was not exposed to the Sterilization cycle.

8.3 Bio-challenge studies

8.3.1 Objective

8.3.1.1 The steam sterilization process, when challenged with Bacillus stearothermophillus biological indicator spore strip/ampoule

spore population of NLT 105 spores strip, should reduce bacterial load by mean of Sterility Assurance Level (SAL) 10-5 Biological

Indicators should be used as per the load.

8.3.1.2 For Porous & Liquid Load at 121ºC – Biological Indicator for Pours & Liquid Load (105 spores of Bacillus stearothermophillus should be used.

8.3.1.3 On incubation of the loaded biological indicator, if growth is observed, then the sterilization cycle parameters are to be reviewed.

8.3.2 Procedure

8.3.2.1 Collect the exposed indicator (during the loaded chamber heat distribution & heat penetration studies) and then send to

microbiology lab for incubation (Incubate the Geobacillus stearothermophillus indicator at 550C to 600C for 7 days).

8.3.2.2 Keep one indicator as a negative control provided by the Mfg of biological indicator as well as one indicator as a

positive control (unexposed biological indicator).

8.3.2.3 Observe any growth for sterility of media & Glassware sterilization cycle. Record the observations on daily

basis in the Annexure. Compile the data generated during the qualification test for complete evaluation of the system.

8.4 Estimation of F0 Value

8.4.1 Objective

8.4.1.1 The calculated F0 value should not be less than the biological F0 value at all temperature mapping locations during the sterilization hold period.

8.4.2 Procedure

8.4.2.1 Record the temperature at all temperature mapping probes during the sterilization hold period in the Annexure.

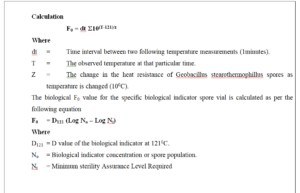

8.4.2.2 Calculate the F0 value at each temperature mapping probe by using the equation as below.

8.4.2.3 Record the F0 value (Results) in the Annexure.

8.4.2.4 Compile the data generated during the qualification test for complete evaluation of the system.

9.0 SET PARAMETER:

| Load description | Sterilization Temperature | No. of cycle | Sterilization Hold time

(Minute) |

| Heat Distribution Empty cycle | 121oC | 1 | 20 |

| Porous Load-

Minimum Load: Sterilization of Glassware (25 Nos Petri plates, 5 Nos sampling bottles), Accessories (5 Nos spatulas, 5 Nos forceps, 5 pairs Hand gloves, 4 Nos Measuring Cylinder, 4 Nos Filtration Assembly. |

121oC | 1 | 20 |

| Maximum Load: Sterilization of Glassware (100 Nos Petri plates, 8 Nos sampling bottles), Accessories (8 Nos spatulas, 8 Nos forceps, 10 pairs Hand gloves, 8 Nos Measuring Cylinder, 6 Nos Filtration Assembly.

|

121oC | 1 | 20 |

| Liquid Load

Minimum Load: Sterilization of Media (2x 100 ml SCDM, 200 ml SCDA, 100 ml SDA 100 ml CA, 100 ml MSA, 100 ml MCA, 2X100 ml MCB, 2x90ml Buffered Sodium chloride Peptone).

|

121oC | 1 | 15 |

| Maximum Load: Sterilization of Media

(10 x100 ml SCDM, 3x400ml SCDA, 10 x 90 ml Buffered Sodium chloride Peptone, 500 ml SDA, 300 ml CA, 300 ml MCA, 300 ml MSA, 10 x100 ml MCB).

|

121oC | 1 | 15 |

10.0 REVALIDATION CRITERIA:

10.1 Any major modification to any part / process of the existing autoclave which must be documented through a change control system.

10.2 Adjustments made in the equipment, as a rectification measure to counter the non compliance of the Results.

11.0 FREQUENCY OF VALIDATION:

11.1 The frequency of Periodic Validation for is yearly basis (±15 Days) for existing systems.

12.0 DEFINITIONS:

12.1 STERILE: In strict sense a specimen would be deemed sterile only when there is complete absence of viable microorganisms from it.

12.2 STERILIZATION: A process, by which all viable microorganisms are removed or destroyed, based on a probability function.

12.3 BIO BURDEN: The number of viable microorganisms in or an object or preparation entering a sterilization step

(usually expressed as colony forming unit per unit volume).

12.4 D VALUE: The D value is the time (in minutes) required to reduce the microbial population by 90% or 1 log cycle (i.e. to a surviving fraction of 1/10).

12.5 Z VALUE: The Z Value is the temp. (in ºC) required for one-log reduction.

12.6 F0 VALUE: The F0 Value is the equivalent time for which a monitored article is exposed to the temperature of 1210 C.

12.7 BIOLOGICAL INDICATORS (BIs): BIs are live spore forms of microorganisms known to be the most resistant living organisms to the

lethal effects of the particular sterilization process. For steam sterilization, the most resistant microorganism is Bacillus stearothermophilus.

12.8 STERILITY ASSURANCE LEVEL (SAL): A term related to the probability of finding a nonsterile unit following a sterilization step.

It is usually expressed in the negative power of 10 (i.e. one in one million = 10 –5).

12.9 PULSE: A sub cycle at the start of Sterilization Cycle in which Vacuum and Steam are alternatively supplied to a steam

sterilizer chamber, for the purpose of removal of air from the chamber.

13.0 REFERENCES:

Schedule – M – “Good Manufacturing Practices and Requirements of Premises, Plant and Equipment for Pharmaceutical Products.”

14.0 DOCUMENTS

14.1 Any Change in the protocol and activity shall be documented and supported with change control.

14.1.1 Protocol No. along with Annexure

14.1.2 The report shall be prepared by Microbiologist, Reviewed by Head-QC and approved by Head-QA. The report shell have following as its Annexure

14.1.3 Calibration certificates.

14.1.4 Certificates of biological indicator.

14.1.5 Chemical indicator.

14.1.6 Any other relevant documents (if any).

15.0 ABBREVIATIONS

15.1 MHS : Moist Heat Sterilizer

15.2 NA : Not Applicable

15.3 RTD : Resistant Temperature Device

15.4 QA : Quality Assurance

15.5 QC : Quality Control

15.6 SAL : Sterility Assurance Level

15.7 °C : Degree Centigrade

15.8 SOP : Standard Operating Procedure

15.9 NMT : Not More Than

15.10 VMP : Validation Master Plan

15.11 BI : Biological Indicators

15.12 A.R. : Analytical Report

15.13 BP : British Pharmacopoeia

15.14 WHO : World Health Organization

15.15 cGMP : Current Good Manufacturing Practice

16.0 DOCUMENT CHANGE HISTORY

First time prepare.

sop for calibration and validation of micro autoclave

sop for Sterility failure investigation

cleaning and operation of discard autoclave

sop for operation of fogger machine

sop for Biological assay of lactic acid bacillus

sop for preparation of culture inoculum

STP for sterility testing of sterile gloves

sop for Operation and calibration of active air sampler

sop for transfer of material for testing and sampling in sterile area

entry & exit procedure in microbiology laboratory

Growth Promotion Test In Microbiology Laboratory

Operation of B.O.D in Microbiology Laboratory

Operation of Horizontal Laminar Air Flow in the microbiology laboratory

Operation and cleaning of Pass Box.

Operation and cleaning of air sampler

Cleaning and Sterilization of Glassware

Analysis of water for microbial load in microbiology lab

Operation and temperature monitoring of Refrigerator

Fumigation of Microbiology Laboratory.

Entry & Exit procedure In Sterility Area

SOP for Microbial analysis of Raw Material Finished Products

SOP for Operation & Calibration of pH meter in Micro Department

SOP for Operation & Calibration of pH meter in Micro Department

SOP Operation and calibration of Hot Air Oven In Microbiology

SOP for operation cleaning & calibration of Digital colony counter

SOP for Operation And Cleaning of Microscope

sop for Media Preparation and Consumption

sop for Receipt Storage and Usage of Culture Media

sop for Cleaning Sanitization And Disinfection In Microbiology

sop for Environmental monitoring of all the Classified area

sop for Handling and Sub culturing of Microbial cultures

sop for Media Growth Promotion Test and various Microbiological test

sop for BOD incubator operation and cleaning

sop sampling of water for microbiological analysis

sop for Disinfectant Efficacy Test

sop for for cleaning and operation of vortex mixture

sop for Temperature & Relative Humidity Monitoring

sop for Operation and Calibration of Heating Block

sop for Sterility Testing of Microbiology

sop for Disposal of Culture Media

sop for Drain point of Microbiology

sop for entry & exit procedure In Microbial limit test and Biosafety

sop for Gram Staining of Bacteria in Microbiology Laboratory

sop for Monitoring of Compressed Air/gases for microbiological analysis

sop for BET (Bacterial Endotoxin) test in Microbiology

sop for receipt storage and Determining the population of Biological indicators

sop for qualification of analyst microbiologist

sop for Bioburden test of Packing materials in Microbiology Laboratory

sop for microbiological assay of erythromycin antibiotic

sop for liquid particle counter

sop for operation and calibration of digital zone reader

sop for monitoring of ultraviolet efficiency LAF and pass box

microbiological assay of cyanocobalamin or vitamin B12

gowning procedure for microbiological testing area

swab testing of various surfaces for bioburden determination

sop for endotoxin challenge test

Hold time study protocol for sterilized media

sop for personnel Qualification protocol for aseptic area

sop for sampling and testing of drain water

Sop for Operation of Airborne Particle Counter

sop for Validation protocol of steam sterilizer autoclave

sop for pathogen detection from drain point

Sop for Analysis of Raw water Purified water water for injection and pure steam water

sop for preservatives efficacy test

sop for collection and preservation of in house isolated microorganisms

sop for Operation Calibration and Maintenance of Micropipette

sop for microbiological testing of water

sop for depyrogenation of apparatus

sop for fertility test growth promotion test of media

sop for Operation and cleaning of moist heat sterilizer

sop for monitoring by active air sampler

sop for swab sampling and testing for clean rooms in production area

sop for monitoring in microbiology laboratory

sop for Fumigation of aseptic area and microbiology lab

sop for monitoring of personnel in aseptic area

sop for maintenance of cultures

sop for Operation and cleaning of laminar bench

sop for monitoring of pure steam

sop for entry and exit procedure to m.l.t and b.e.t room

sop for storage of and use of media

sop for disposal of microbiological media and cleaning of microbiological glassware