sop of Microbiological assay

1.0 Objective

To lay down a procedure for microbiological assay of raw material and finished product by cup plate method

2.0 Scope

This Standard Operating Procedure is applicable for the Microbiological assay of raw material and finished

product by cup plate method at formulation plant of abc company.

3.0 Responsibility

3.1 Officer/Executive Quality Control shall be responsible for determination of microbiological assay.

3.2 Head Quality Control is responsible for the compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure;

QA : Quality Assurance

LAF : Laminar Air Flow

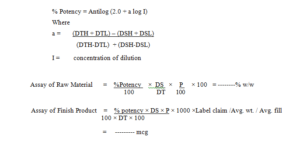

DTH : Mean diameter of the sample dilution (Higher)

DTL : Mean diameter of the sample dilution (Lower)

DSH : Mean diameter of the standard dilution (Higher)

DSL : Mean diameter of the sample dilution (Lower)

° C : Degree Centigrade

SS : Stainless Steel

Hrs : Hours

Ml : Millilitre

DS : Dilution factor of standard solution

DT : Dilution factor of sample solution

P : Potency of vitamin Working standard (on as bases)

5.0 Procedure

5.1 Prepare microbiological assay medium as per specification given in monograph.

5.2 Requirements.

5.2.1 For standard cultures.

5.2.2 Micropipette 20µl to 200 µl, 1000 µl,

5.2.3 Sterile cork borer

5.2.4 Sterile measuring cylinder.

5.2.5 Sterile Petri dish.

5.2.6 Working Standard.

5.3 Preparation of inoculum:

5.3.1 Before starting antibiotic/vitamin assay, prepare fresh culture slant and incubate at 30 ºC to 35 ºC for 24 hrs.

5.3.2 Take one loop full culture from slant tube and inoculated in 10 ml of 0.9% normal saline solution and use it as inoculum.

5.4 Preparation standard and test dilution:

5.4.1 Make standard dilution with reference standard or working standard for DSH and DSL dilution.

5.4.2 In same manner make DTH dilution and DTL dilution as per requirements.

5.5 Assay method:

5.5.1 Aseptically transfer 10 ml (approx) of prepared culture inoculum into the vitamin assay medium.

5.5.2 After mixing of culture inoculum into media, aseptically pour 25 ml media in each of Petri plates.

5.5.3 After solidification make 4 holes in each media plates with the help of 6 to 8 mm SS borer.

5.5.4 Mark (DSH, DSL, DTH, and DTL) on the back side of media plate where respective dilution shall be poured.

5.5.5 Pour 100 µl of the test and standard dilution in their respective holes.

5.5.6 Keep the plates undisturbed at room temperature for about 15 min.

5.5.7 Incubate these plates in the incubator at 30 to 35º C for 24 hrs.

5.5.8 After incubation measure the zone of exhibition by vernier scale.

5.5.9 Calculate the Assay and record the results as per the current version of Annexure.

.

.

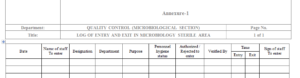

6.0 Forms and Records

6.1 Microbiological Assay Analysis record – Annexure-1

6.2 Vitamin B12 assay report for finished Product – Annexure-2

6.3 Vitamin B12 assay report for raw material – Annexure-3

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Control copy – Quality Control

8.0 History

| Revision Number | Details For Change |

Reason for Revision |

| 00 | New SOP | NA |

sop for calibration and validation of micro autoclave

sop for Sterility failure investigation

cleaning and operation of discard autoclave

sop for operation of fogger machine

sop for Biological assay of lactic acid bacillus

sop for preparation of culture inoculum

STP for sterility testing of sterile gloves

sop for Operation and calibration of active air sampler

sop for transfer of material for testing and sampling in sterile area

entry & exit procedure in microbiology laboratory

Growth Promotion Test In Microbiology Laboratory

Operation of B.O.D in Microbiology Laboratory

Operation of Horizontal Laminar Air Flow in the microbiology laboratory

Operation and cleaning of Pass Box.

Operation and cleaning of air sampler

Cleaning and Sterilization of Glassware

Analysis of water for microbial load in microbiology lab

Operation and temperature monitoring of Refrigerator

Fumigation of Microbiology Laboratory.

Entry & Exit procedure In Sterility Area

SOP for Microbial analysis of Raw Material Finished Products

SOP for Operation & Calibration of pH meter in Micro Department

SOP for Operation & Calibration of pH meter in Micro Department

SOP Operation and calibration of Hot Air Oven In Microbiology

SOP for operation cleaning & calibration of Digital colony counter

SOP for Operation And Cleaning of Microscope

sop for Media Preparation and Consumption

sop for Receipt Storage and Usage of Culture Media

sop for Cleaning Sanitization And Disinfection In Microbiology

sop for Environmental monitoring of all the Classified area

sop for Handling and Sub culturing of Microbial cultures

sop for Media Growth Promotion Test and various Microbiological test

sop for BOD incubator operation and cleaning

sop sampling of water for microbiological analysis

sop for Disinfectant Efficacy Test

sop for for cleaning and operation of vortex mixture

sop for Temperature & Relative Humidity Monitoring

sop for Operation and Calibration of Heating Block

sop for Sterility Testing of Microbiology

sop for Disposal of Culture Media

sop for Drain point of Microbiology

sop for entry & exit procedure In Microbial limit test and Biosafety

sop for Gram Staining of Bacteria in Microbiology Laboratory

sop for Monitoring of Compressed Air/gases for microbiological analysis

sop for BET (Bacterial Endotoxin) test in Microbiology

sop for receipt storage and Determining the population of Biological indicators

sop for qualification of analyst microbiologist

sop for Bioburden test of Packing materials in Microbiology Laboratory

sop for microbiological assay of erythromycin antibiotic

sop for liquid particle counter

sop for operation and calibration of digital zone reader

sop for monitoring of ultraviolet efficiency LAF and pass box

microbiological assay of cyanocobalamin or vitamin B12

gowning procedure for microbiological testing area

swab testing of various surfaces for bioburden determination

sop for endotoxin challenge test

Hold time study protocol for sterilized media

sop for personnel Qualification protocol for aseptic area

sop for sampling and testing of drain water

Sop for Operation of Airborne Particle Counter

sop for Validation protocol of steam sterilizer autoclave

sop for pathogen detection from drain point

Sop for Analysis of Raw water Purified water water for injection and pure steam water

sop for preservatives efficacy test

sop for collection and preservation of in house isolated microorganisms

sop for Operation Calibration and Maintenance of Micropipette

sop for microbiological testing of water

sop for depyrogenation of apparatus

sop for fertility test growth promotion test of media

sop for Operation and cleaning of moist heat sterilizer

sop for monitoring by active air sampler

sop for swab sampling and testing for clean rooms in production area

sop for monitoring in microbiology laboratory

sop for Fumigation of aseptic area and microbiology lab

sop for monitoring of personnel in aseptic area

sop for maintenance of cultures

sop for Operation and cleaning of laminar bench

sop for monitoring of pure steam

sop for entry and exit procedure to m.l.t and b.e.t room

sop for storage of and use of media

sop for disposal of microbiological media and cleaning of microbiological glassware

Preparation Filtration Usage and Destruction of Disinfectant Solution

Entry Exit and gowning Procedure in Microbiology Laboratory

Safety measures to be followed in microbiology laboratory

Growth Promotion Test of Media

Preservation and Maintenance of Microbial Strain

Entry and Exit in Microbiology Sterile Area

Entry and Exit in Microbiology Limit testing area

Water sampling of raw water purified water WFI and PSG in microbiology Lab