STP for sterility testing of sterile gloves

1 OBJECTIVE

To describe the procedure for the sterility testing of sterile gloves.

The purpose of this exercise is to ensure that the gloves are free from any microbial contamination.

2 SCOPE

This procedure is applicable for the sterility testing of sterile gloves

3 RESPONSIBILITY

Microbiologist

4 ACCOUNTABILITY

Manager -QC

5 ABBREVIATIONS

QA : Quality Assurance

QC : Quality Control

HLAF : Horizontal Laminar Air Flow

IPA : Isopropyl Alcohol

WFI : Water for injection

SCDM : Soyabean Casein Digest Media

FTGM : Fluid Thioglycollate Media

NO. : Number

RH : Relative humidity

UV : Ultra-violet

6 PRECAUTIONS

6.1 All the apparatus and material used for sterility should be sterile.

6.2 All accessories like scissor and forceps used during test should be sterilized time to time with flame.

6.3 Media should be clear and free from particles.

6.4 Use proper sterile dress during test.

6.5 No other person except microbiologist is allowed to go inside the sterility room.

6.6 Start the work after proper environmental conditions are maintained for sterile area.

6.7 Cut the sterile gloves with the help of scissor near flame.

6.8 Always check sterilization status for validity of all the materials before using for sterility test.

7 MATERIAL REQUIRED

Glass beaker, Sterile forceps, Sterile scissor, Soybean casein digest media, Fluid thioglycollate media Peptone water, Sterile garments,

Sterile gloves, Isopropyl Alcohol 70% (Filtered), Disinfectant solution, Tray, SS table, Sterilization indicator strips, glass bottles,

Aluminium foil, Non absorbent cotton, sterility test tube, glass bottles, Standard Positive Cultures- Bacillus subtilis

(aerobic bacteria), S. aureus (aerobic bacteria), P. aeruginosa (aerobic bacteria), Cl. sporogenes (anaerobic bacteria),

Candida albicans (fungus ), Aspergillus brasiliensis (fungus), Environmental Isolate.

8 EQUIPMENT REQUIRED

Double door autoclave, Laminar Air Flow, Bunsen burner, BOD incubator maintained at 22.5˚ + 2.5˚C for fungal growth,

BOD incubator maintained at 32.5 ˚+ 2.5˚C for bacterial growth.

9 PROCEDURE

9.1 Pre Preparation

9.1.1 Maintain the sterile condition of area by fumigation before performing the test as per

SOP if required.

9.1.2 Maintain the environment condition of the area before start of the work.

9.1.3 Check the relative humidity and temperature of the sterility area prior to the sterility testing as per

SOP. In sterility room % RH should be within 55+ 5% & temperature should

be 27˚C + 2˚C.

9.1.4 Sterile media at 121˚C for 20 minutes and accessories at 121˚C for 30 minutes before start of the

work as per SOP

9.1.5 Place sterile garments in garment cubicle provided in sterility area.

9.1.6 Place sample in Dynamic pass box after cleaned with filtered 70% IPA

solution using lint free cloth.

9.1.7 Switch on UV light and blower of HLAF 30 minutes before start the work.

9.2 Media preparation –

9.2.1 Soybean casein digest media- Weigh dehydrated media as per the requirement and dissolve the

weighed qty. in sufficient quantity of WFI to get required concentration as per manufacturer

(written on the container) of media.

9.2.2 Fluid Thioglycollate media- Weigh dehydrated media as per the requirement and dissolve the

weighed qty. in sufficient quantity of WFI to get required concentration as per manufacturer

(written on the container) of media.

9.2.4 Transfer 500ml of each media, SCDM & FTGM in bottles separately for test. Close the lids of

bottles and cover with aluminium foil. For media and positive control transfer 100 ml of each

media, SCDM & FTGM in test tubes separately. Plug the tubes with non absorbent cotton and

cover with Aluminum foil.

9.3 Sterilization of media and utensils-

Place the media bottles and tubes in autoclave and sterilize at 121˚C for 20 minutes and

other accessories like scissor, forcep for 30 minutes. Also place steam sterilization chemical

indicator inside the autoclave for sterilization verification for each cycle.

9.4 Arrangement of sample-

Take two pair of gloves of the lot to be tested. Keep it in a tray mopped with filtered 70% IPA.

9.5 Test procedure –

9.5.1 Cleaning of Sterility room-Enter into the sterile area as per SOP for Entry/Exit to Micro Lab

Clean the sterility room as per SOP for Cleaning of Micro Lab

9.5.2 Before entering in sterile area ensure that the samples are kept in the dynamic pass box.

9.5.3 After 20 minutes enter into the sterile area as per SOP for Entry/Exit to Micro Lab

9.5.4 Take out the contact plates from the dynamic pass box and carry out finger dab as per SOP for

Environmental monitoring in Third change room.

9.5.5 Collect samples from dynamic pass box and take them into sterility room & place them on SS table and

ensure that the UV light of HLAF is turned “ON” before 30 minutes.

9.5.6 Collect the sterility media bottles and tubes, equipments required for sterility test & take to the

Sterility room. Place them of SS table.

9.5.7 Switch “OFF” UV light of HLAF.

9.5.8 Mop the HLAF bench with filtered 70% IPA by using sterile lint free mops.

9.5.9 Spray filtered 70% IPA on the media bottles, tubes and on hands. Place media bottles and tubes

on HLAF bench.

9.5.10 Mark the media bottles with details like Product Name, lot No and starting date before

Performing the test.

9.5.11 Take out the gloves aseptically. Cut them with the help of sterile scissor into pieces near flame.

9.5.12 Add them into media bottles (Fluid Thioglycollate media and Soybean casein digest media)

9.5.12 Close the lids tightly.

9.5.13 Take one tube of each media, Fluid Thioglycollate media and Soybean casein digest media,

Mark them as media control.

9.5.14 Perform the test for positive control in MLT room. Bring the media tube for positive control to

MLT room.

9.5.15 Make a positive control tube by transferring 1ml suspension of working dilution of standard

Culture to the SCDM and FTGM as per table 1 of SOP for Growth Promotion test

9.5.25 Incubate FTGM bottles of test, tubes of media control for 14 days and tubes of Positive Control

for 5 days at 32.5˚C + 2.5˚C to detect the bacterial growth & incubate SCDM bottles of test,

tubes of media control for 14 days and tubes of positive control for 5 days at 22.5˚C + 2.5˚C for

the detection of fungi.

9.5.26 Observe each test bottle daily and record the results as positive or negative growth. The

Medium should be clear and transparent .The sample passes the sterility test and test is valid

only if positive control shows growth with turbidity and negative remains clear without growth.

10 ENCLOSURES

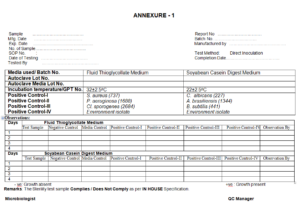

ANNEXURE -1 STERILITY OBSERVATION SHEET OF STERILE GLOVES

11 REFERENCE

In House

sop for calibration and validation of micro autoclave

sop for Sterility failure investigation

cleaning and operation of discard autoclave

sop for operation of fogger machine

sop for Biological assay of lactic acid bacillus

sop for preparation of culture inoculum

STP for sterility testing of sterile gloves

sop for Operation and calibration of active air sampler

sop for transfer of material for testing and sampling in sterile area

entry & exit procedure in microbiology laboratory

Growth Promotion Test In Microbiology Laboratory

Operation of B.O.D in Microbiology Laboratory

Operation of Horizontal Laminar Air Flow in the microbiology laboratory

Operation and cleaning of Pass Box.

Operation and cleaning of air sampler

Cleaning and Sterilization of Glassware

Analysis of water for microbial load in microbiology lab

Operation and temperature monitoring of Refrigerator

Fumigation of Microbiology Laboratory.

Entry & Exit procedure In Sterility Area

SOP for Microbial analysis of Raw Material Finished Products

SOP for Operation & Calibration of pH meter in Micro Department

SOP for Operation & Calibration of pH meter in Micro Department

SOP Operation and calibration of Hot Air Oven In Microbiology

SOP for operation cleaning & calibration of Digital colony counter

SOP for Operation And Cleaning of Microscope

sop for Media Preparation and Consumption

sop for Receipt Storage and Usage of Culture Media

sop for Cleaning Sanitization And Disinfection In Microbiology

sop for Environmental monitoring of all the Classified area

sop for Handling and Sub culturing of Microbial cultures

sop for Media Growth Promotion Test and various Microbiological test

sop for BOD incubator operation and cleaning

sop sampling of water for microbiological analysis

sop for Disinfectant Efficacy Test

sop for for cleaning and operation of vortex mixture

sop for Temperature & Relative Humidity Monitoring

sop for Operation and Calibration of Heating Block

sop for Sterility Testing of Microbiology

sop for Disposal of Culture Media

sop for Drain point of Microbiology

sop for entry & exit procedure In Microbial limit test and Biosafety

sop for Gram Staining of Bacteria in Microbiology Laboratory

sop for Monitoring of Compressed Air/gases for microbiological analysis

sop for BET (Bacterial Endotoxin) test in Microbiology

sop for receipt storage and Determining the population of Biological indicators

sop for qualification of analyst microbiologist

sop for Bioburden test of Packing materials in Microbiology Laboratory

sop for microbiological assay of erythromycin antibiotic

sop for liquid particle counter

sop for operation and calibration of digital zone reader

sop for monitoring of ultraviolet efficiency LAF and pass box

microbiological assay of cyanocobalamin or vitamin B12

gowning procedure for microbiological testing area

swab testing of various surfaces for bioburden determination

sop for endotoxin challenge test

Hold time study protocol for sterilized media

sop for personnel Qualification protocol for aseptic area

sop for sampling and testing of drain water

Sop for Operation of Airborne Particle Counter

sop for Validation protocol of steam sterilizer autoclave

sop for pathogen detection from drain point

Sop for Analysis of Raw water Purified water water for injection and pure steam water

sop for preservatives efficacy test

sop for collection and preservation of in house isolated microorganisms

sop for Operation Calibration and Maintenance of Micropipette

sop for microbiological testing of water

sop for depyrogenation of apparatus

sop for fertility test growth promotion test of media

sop for Operation and cleaning of moist heat sterilizer

sop for monitoring by active air sampler

sop for swab sampling and testing for clean rooms in production area

sop for monitoring in microbiology laboratory

sop for Fumigation of aseptic area and microbiology lab

sop for monitoring of personnel in aseptic area

sop for maintenance of cultures

sop for Operation and cleaning of laminar bench

sop for monitoring of pure steam

sop for entry and exit procedure to m.l.t and b.e.t room

sop for storage of and use of media

sop for disposal of microbiological media and cleaning of microbiological glassware