Operation and Calibration of Microscope

1.0 Objective

To lay down a procedure for Operation and calibration of Microscope.

2.0 Scope

This Standard Operating Procedure at Microbiology laboratory Quality control department of abc company,

3.0 Responsibility

3.1 Concerned Officer/Executive shall be responsible to follow this SOP.

3.2 Department Head or his/her designee shall be responsible to implement and ensuring to compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

QC : Quality Control

QA : Quality Assurance

SD : Standard deviation

Cal : Calibration

5.0 Procedure

5.1 Microscope is used for identification of Microscopic Characteristics of drug substance.

5.2 Make sure all the exposed optical surfaces are free of dirt. Plug the power cord into grounded outlet

(ensure that power supply plug is properly grounded otherwise it may damage the power supply transformer.

Switch on supply and keep regulator in medium position.

5.3 Adjust the observation Head to convenient working position.

5.4 Rotate the nosepiece until the lowest power objectives, the greater the area of the speci men surface included

in the field of view. Lower power objectives also have a much greater depth if focus and use fir initial focusing

and viewing.

5.5 Take down the stage surface to a fairly low position with the help of coarse focus knob.

5.6 Make sure that the stage surface is free of dust, grit or any other material that will interfere with the

movement of the specimen slide across the surface of the stage or scratch the stage. Position the specimen area

of the slide (cover glass up –wards) over the center of the stage aperture use the stage control knob to move the

specimen slide to the desired position.

5.7 Looking through the Binocular Head, raise the stage by adjusting the coarse focus knob until an image

appears-thereafter.

5.8 Adjust with the help of fine focus knobs to sharpen the image.

5.9 Look at the image and adjust the condenser aperture to obtain the best possible resolution. The clarity

of the image depends upon the size of the aperture. As the aperture becomes smaller. As aperture becomes

smaller, the contras and the depth of focus increases. The clearest image is produced by combination of these factors.

5.10 Examine the specimen. When you find a feature you wish to observe at a higher magnification, move

the slide so that the feature gets centered in the field of view.

5.11 Until you gain sufficient experience in use of this microscope, it is wise to always obtain an image with lowest power objectives and then going to successively higher power objectives one step at a time.

5.12 When using objectives of higher numerical aperture proper focusing of the abbe condenser is important.

Move the abbe condenser by racking the condenser movement knob, up down so that the field is evenly illuminated.

5.13 This microscope has a rotating potentiometer for regulating the light intensity. Rotate the potentiometer

knob from low to high as you go from low magnification to high magnification objectives for obtaining best

light in the field of view.

5.14 The procedure for the examine a specimen using the oil immersion objectives is as follow:

5.15 Rotate the nosepiece so the low power objective (10X) is in the light path.

5.16 Place the one-drop of immersion oil on the lighted area of the specimen slide.

5.17 Rotate the nosepiece so the low power objective100X oil immersion objectives are in the light path.

Be cautious than 40X objective should not get in contact with oil.

5.18 Since all the objectives are Para focal, the specimen shall be visible when changed to 100X.

Use fine Focus knob to get the best image.

5.19 After each session when you finish using the oil immersion objectives, wipe off the traces of oil

from the objective, and the specimen if it is with cover glass, with a lens issue or clean soft cloth moist with

lens cleaning solution.

5.20 Calibration

5.20.1 Calibration shall be performed for accuracy of microns with calibrated micrometer by authorized

out source calibration party once a six months and when ever a major maintenance is done.

5.21 General

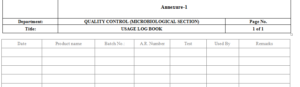

5.21.1 Record the every usage in form as given in Annexure-1.

5.21.2 Document the calibration record is provided by out source calibration party.

6.0 Forms and Records

6.1 Usage log – Annexure-1

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Control copy – Quality Control

8.0 History

| Revision Number | Details For Change |

Reason for Revision |

| 00 | New SOP | NA |

sop for calibration and validation of micro autoclave

sop for Sterility failure investigation

cleaning and operation of discard autoclave

sop for operation of fogger machine

sop for Biological assay of lactic acid bacillus

sop for preparation of culture inoculum

STP for sterility testing of sterile gloves

sop for Operation and calibration of active air sampler

sop for transfer of material for testing and sampling in sterile area

entry & exit procedure in microbiology laboratory

Growth Promotion Test In Microbiology Laboratory

Operation of B.O.D in Microbiology Laboratory

Operation of Horizontal Laminar Air Flow in the microbiology laboratory

Operation and cleaning of Pass Box.

Operation and cleaning of air sampler

Cleaning and Sterilization of Glassware

Analysis of water for microbial load in microbiology lab

Operation and temperature monitoring of Refrigerator

Fumigation of Microbiology Laboratory.

Entry & Exit procedure In Sterility Area

SOP for Microbial analysis of Raw Material Finished Products

SOP for Operation & Calibration of pH meter in Micro Department

SOP for Operation & Calibration of pH meter in Micro Department

SOP Operation and calibration of Hot Air Oven In Microbiology

SOP for operation cleaning & calibration of Digital colony counter

SOP for Operation And Cleaning of Microscope

sop for Media Preparation and Consumption

sop for Receipt Storage and Usage of Culture Media

sop for Cleaning Sanitization And Disinfection In Microbiology

sop for Environmental monitoring of all the Classified area

sop for Handling and Sub culturing of Microbial cultures

sop for Media Growth Promotion Test and various Microbiological test

sop for BOD incubator operation and cleaning

sop sampling of water for microbiological analysis

sop for Disinfectant Efficacy Test

sop for for cleaning and operation of vortex mixture

sop for Temperature & Relative Humidity Monitoring

sop for Operation and Calibration of Heating Block

sop for Sterility Testing of Microbiology

sop for Disposal of Culture Media

sop for Drain point of Microbiology

sop for entry & exit procedure In Microbial limit test and Biosafety

sop for Gram Staining of Bacteria in Microbiology Laboratory

sop for Monitoring of Compressed Air/gases for microbiological analysis

sop for BET (Bacterial Endotoxin) test in Microbiology

sop for receipt storage and Determining the population of Biological indicators

sop for qualification of analyst microbiologist

sop for Bioburden test of Packing materials in Microbiology Laboratory

sop for microbiological assay of erythromycin antibiotic

sop for liquid particle counter

sop for operation and calibration of digital zone reader

sop for monitoring of ultraviolet efficiency LAF and pass box

microbiological assay of cyanocobalamin or vitamin B12

gowning procedure for microbiological testing area

swab testing of various surfaces for bioburden determination

sop for endotoxin challenge test

Hold time study protocol for sterilized media

sop for personnel Qualification protocol for aseptic area

sop for sampling and testing of drain water

Sop for Operation of Airborne Particle Counter

sop for Validation protocol of steam sterilizer autoclave

sop for pathogen detection from drain point

Sop for Analysis of Raw water Purified water water for injection and pure steam water

sop for preservatives efficacy test

sop for collection and preservation of in house isolated microorganisms

sop for Operation Calibration and Maintenance of Micropipette

sop for microbiological testing of water

sop for depyrogenation of apparatus

sop for fertility test growth promotion test of media

sop for Operation and cleaning of moist heat sterilizer

sop for monitoring by active air sampler

sop for swab sampling and testing for clean rooms in production area

sop for monitoring in microbiology laboratory

sop for Fumigation of aseptic area and microbiology lab

sop for monitoring of personnel in aseptic area

sop for maintenance of cultures

sop for Operation and cleaning of laminar bench

sop for monitoring of pure steam

sop for entry and exit procedure to m.l.t and b.e.t room

sop for storage of and use of media

sop for disposal of microbiological media and cleaning of microbiological glassware

Preparation Filtration Usage and Destruction of Disinfectant Solution

Entry Exit and gowning Procedure in Microbiology Laboratory

Safety measures to be followed in microbiology laboratory

Growth Promotion Test of Media

Preservation and Maintenance of Microbial Strain

Entry and Exit in Microbiology Sterile Area

Entry and Exit in Microbiology Limit testing area

Water sampling of raw water purified water WFI and PSG in microbiology Lab

Microbial monitoring of Drain points

sop for Operation of Double Door Autoclave

Operation and Calibration of Thermo block

Operation and Calibration of Micro pipette