Filter Cleaning of HVAC System RLAF & LAF

1.0 Objective

To lay down a procedure for Filters Cleaning of HVAC System, RLAF & LAF.

2.0 Scope

This Standard Operating Procedure is applicable for various types of Filters (Fresh Air, Primary & secondary) fitted in HVAC System, RLAF & LAF to be followed at formulation plants

3.0 Responsibility

3.1 Engineering Officer / Executive shall be responsible for the execution of this procedure.

3.2 Engineering Manager shall be responsible for the implementation of this SOP.

3.3 Head QA/Designee should be responsible for compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

No : Number

QC : Quality Control

Qty : Quantity

TAC : Tablet and Capsule

DPI : Dry Powder Injection

L&L : Liquid and Lozenges

MB : Microbiology

APU : Air Processing Unit

5.0 Procedure

5.1 Frequency: The cleaning frequency of filter is as follows:

S.No. DESCRIPTION FREQUENCY

1 Pre-Filters and Fresh air Filters of AHUs Catering to all Process area of TAC , L&L and DPI Block Fortnightly

2 MV Filter of AHUs Catering to all Process area of TAC , L&L and DPI Block Fortnightly

3 APU Filters of All Fluid Bed Driers And, All Coating Machines Fortnightly

4 Filter Cleaning of Reverse Laminar Air Flow for dispensing and sampling booth Fortnightly

5 Filter Cleaning of Laminar Air Flow Monthly

5.2 Cleaning of AHU filters:

5.2.1 Ensure that no production activities are being carried out in respective area for which filter cleaning is scheduled.

5.2.2 Clean the filters if the differential pressure across the filter exceed beyond the specified limit or as per the scheduled whichever is earlier.

5.2.3 Switch off the AHU and isolate the power supply.

5.2.4 Put “FILTER CLEANING UNDER PROGRESS “Tag on the Panel.

5.2.5 Personnel protective equipments like nose mask, safety goggles and rubber hand gloves shall be used.

5.2.6 Open the door of respective AHU and take out the filters from AHU and pack in polythene bag with label as “To be cleaned”.

5.2.7 Clean the plenum with dry cloth thoroughly and ensure that there is no dust accumulation in the plenum joint panels.

5.2.8 Carry all the filters to a filter cleaning Station.

5.2.9 Remove the filters from polythene bags and place the entire filter at the filter cleaning station for cleaning Purpose. Discard the used polythene bags.

5.2.10 Place the filters from the top on to the filter support frame with dirty side facing downward.

5.2.11 Clean the filters with compressed air with a pressure between 0.5 -1.0 Kg/cm².

5.2.12 Check the filters visually if found dirty then clean the filter with water with the help of water gun.

5.2.13 Dry the filter by blowing compressed air in the direction to that of normal air flow direction.

5.2.14 Check & ensure the filter is cleaned & look for the damages visually.

5.2.15 During inspection of filters if found any discrepancy, take new filter from stores ensure that size of filter is identical with the damaged one. Ensure visually the cleanliness of the new filter.

5.2.16 After cleaning & air drying put the cleaned filters in clean polythene bags and re-fix the filters.

5.2.17 After re-fixing the filters run the AHU and take the differential pressure reading across the filter for confirming the proper cleaning and integrity of the filters.

5.2.18 If differential pressure across the filter found very low then it is confirmed that the filter is damaged then replaced the same and if differential pressure across the filter found very high then it is confirmed then the filters is clogged and replaced the same with new one.

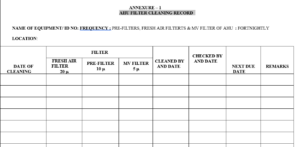

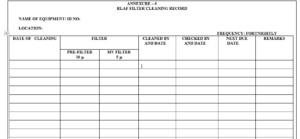

5.2.19 Record the cleanliness of filter as shown in Annexure – 1, 2, 3&4.

5.3 Cleaning Of Process Equipments APU Filters (FBD And Coating )

5.3.1 This procedure is applicable for cleaning the APU filters of All FBDs, and all Coating machines.

5.3.2 Take all the safety precaution prior to cleaning the APU filters of FBD and Coating. Ensure that power supply of these equipments switched off.

5.3.3 Take out the unclean filters from respective APU unit of FBD or Coating.

5.3.4 Repeat the procedure as mentioned in 5.2.7 to 5.2.17.

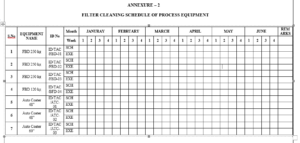

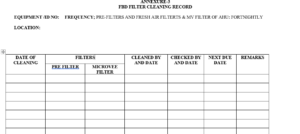

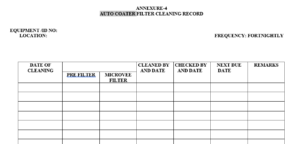

5.3.5 Record the status of the filter cleaning as shown in Annexure – 1, 2, 3&4.

5.3.6 Filter cleaning can be done with in the period of ± one week under following conditions:

Non availability of machines/Area

Holiday

5.4 Cleaning of Reverse Laminar Air Flow.

5.4.1 Ensure that no dispensing / sampling activities are being carried out in respective area for which filter cleaning is scheduled.

5.4.2 Switch off the RLAF and isolate the power supply.

5.4.3 Put “FILTER CLEANING UNDER PROGRESS “Tag on the Panel.

5.4.4 Personnel protective equipments like nose mask, safety goggles and rubber hand gloves shall be used.

5.4.5 Open the cover of respective RLAF and take out the filters from RLAF and pack in polythene bag with label as “To be cleaned”..

5.4.6 Carry all the filters to a filter cleaning Station.

5.4.7 Remove the filters from polythene bags and place the entire filter at the filter cleaning station for cleaning Purpose. Discard the used polythene bag.

5.4.8 Place the filters from the top on to the filter support frame with dirty side facing downward.

5.4.9 Repeat the procedure as mentioned in 5.2.7 to 5.2.17.

5.4.10 Record the cleanliness of filter as shown in Annexure – 5

5.4.11 Filter cleaning can be done with in the period of ± one week under following conditions:

Non availability of machines/Area

Holiday

5.5 Cleaning of Filter of Laminar Air Flow.

5.5.1 Ensure that no activities are being carried out in respective area for which filter cleaning is scheduled.

5.5.2 Switch off the LAF and isolate the power supply.

5.5.3 Put “FILTER CLEANING UNDER PROGRESS “Tag on the Panel.

5.5.4 Personnel protective equipments like nose mask, safety goggles and rubber hand gloves shall be used.

5.5.5 Open the cover of respective LAF and take out the filters from LAF and pack in polythene bag with label as “To be cleaned”..

5.5.6 Carry all the filters to a filter cleaning Station.

5.5.7 Remove the filters from polythene bags and place the entire filter at the filter cleaning station for cleaning Purpose. Discard the used polythene bag.

5.5.8 Place the filters from the top on to the filter support frame with dirty side facing downward.

5.5.9 Repeat the procedure as mentioned in 5.2.7 to 5.2.17.

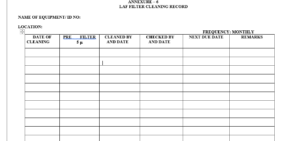

5.5.10 Record the cleanliness of filter as shown in Annexure – 6

5.5.11 Filter cleaning can be done with in the period of ± one week under following conditions:

Non availability of machines/Area

Holiday

6.0 Forms and Records

6.1 Record of AHU filter cleaning – Annexure -1

6.2 Filter Cleaning schedule of process equipment – Annexure -2

6.3 Record of FBD filter cleaning – Annexure -3

6.4 Record of Auto-Coater filter cleaning – Annexure -4

6.5 Record of RLAF filter cleaning – Annexure -5

6.6 Record of LAF filter cleaning – Annexure -6

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Controlled copies – Engineering Department

sop for Execution of Preventive Maintenance

Preparation of Sodium Hydroxide Solution

sop for water cooled chiller operation

cleaning and preventive maintenance of LAF and RLAF

sop for replacement of water system filters

cleaning and preventive maintenance of insectocutor

sop for operation of preventive maintenance

sop for material receiving and consumption record

sop for Preventive maintenance of bottle washing machine

sop for Replacement of Battery of Electronic Devices

sop for Preparation of R.O. Antiscalant Solution

Preventive Maintenance of Rapid Cooling Steam Sterilizer

Preventive Maintenance of Rapid cooling steam Generator

sop for Preventive Maintenance of Dust Collector

sop for Replacement of HVAC filters

SOP for Battery Backup in Mobile Laminar Air Flow Trolley

sop for Replacement of Tube lights

sop for Replacement of UV light of purified water plant

sop for Cleaning of soft water storage tank and RO feed tank

sop for Preparation of Sodium hydroxide Solution

sop for Operation and regeneration of softener plant

Procedure Of Issuance Of material from Engineering Store

sop for Preventive Maintenance of Filter Press

sop for Preventive Maintenance of Sugar Transfer System

sop for Preventive Maintenance of Shrink Sleeve Machine

sop for Preventive Maintenance of ROPP Cap Elevator

sop for Preventive Maintenance of Liquid Transfer Pumps

sop for Preventive Maintenance of Liquid Tanks

Preventive Maintenance of Strip De-Foiling Machine

sop for Preventive Maintenance of Colloidal Mill

sop for Preventive Maintenance of Packing Collator Belt

sop for Checking light intensity

sop for Operation of Fire- Extinguisher

sop for Passivation of WFI Distribution Loop

sop for Analysis of Effluent Treatment Plant Water

sop for Methodology to Dispose ETP Sludge

sop for Action Plan In Case Of Electrical Power Failure

sop for Colour Coding of Piping and Accessories of Utilities

sop for Disposal of Engineering Waste

Filter Cleaning of HVAC System RLAF & LAF

Procedure for Calibration of Magnehelic Gauge

Procedure for Calibration of Vacuum Gauge

Procedure for Calibration of Pressure Gauge

sop for Procedure for Calibration of Temperature Controller

sop for Preventive Maintenance of Infrared Dryer Umbrella Type

sop for Preventive Maintenance of Battery stacker

sop for Preventive Maintenance of Lift

sop for Preventive Maintenance of Vacuum Cleaner

sop for Preventive Maintenance of laminar air flow unit

sop for Preventive Maintenance of Lozenges Manufacturing Line

sop for Preventive Maintenance of Garment Washing Machine

sop for Preventive Maintenance of Multi Column Distillation Plant

sop for Preventive Maintenance of Steam Sterilizer Autoclave

sop for Preventive Maintenance of Pure steam Generator

sop for Preventive maintenance of Depyrogenating Tunnel

sop for Preventive Maintenance of vial sealing machine

sop for preventive maintenance of Powder Filling and Rubber Stoppering machine

sop for Preventive Maintenance of Vial Washing Machine

sop for Preventive Maintenance of Inspection Table

sop for Preventive Maintenance of Hi-Cart

sop for Preventive Maintenance of Turn table

sop for Preventive Maintenance of sticker labeling machine

sop for Preventive Maintenance of Liquid Filling and Sealing Machine

sop for Preventive Maintenance of Linear Bottle Washing Machine

sop for Preventive Maintenance of De-Foiling Machine

sop for Preventive Maintenance of Strip Packing Machine

sop for Preventive Maintenance of Blister Packing Machine

sop for Preventive Maintenance of Capsule Polishing and Sorting Machine

sop for Preventive Maintenance of Capsule Filling Machine

sop for Preventive maintenance of Auto Coater

sop for Preventive Maintenance of Compression Machine

sop for preventive maintenance of packing conveyor belt

sop for Preventive Maintenance of Sifter Cum Multi mill

sop for Preventive Maintenance of Rapid Mixer Granulator

sop for Preventive Maintenance Of Fluid Bed Dryer

sop for Preventive Maintenance of Octagonal Blender

sop for Preventive Maintenance of Lifting and Positioning Device

sop for Preventive Maintenance of Paste Preparation vessel

sop for preventive maintenance of Vibro-Sifter

sop for preventive maintenance of air curtain

sop for preventive maintenance of air handling units

Preventive Maintenance of Diesel Generator

sop for Preventive Maintenance of cooling towers

sop for Preventive Maintenance of Boiler

sop for Preventive Maintenance of Air Compressor

sop for Preventive Maintenance of Chilling Plant

sop for Preventive Maintenance of Transformers

sop for Preventive maintenance of Purified Water System

sop for Break Down maintenance of Machine and Work Requisition

sop for Operation of Dust Extraction System

sop for Operation Of Effluent Treatment Plant

sop for Operation Of Diesel Generator

sop for Operation of Multi Column Distillation Plant

sop for Operation of Pure Steam Generator

sop for Operation of Air Handling Unit

sop for Operation of Cooling Tower

sop for Operation of Air Compressor

sop for Operation of Water Chilling Plant

sop for Cleaning of Pure Steam Generator

Cleaning of Over Head Water Tanks HDPE

sop for Cleaning of Water tanks

sop for Sanitization of multi column plant

sop for Sanitization of Ultrafiltration System

Sop for Chemical Sanitization of Reverse Osmosis

Sop for Sanitization of Hot Sanitization & Electro Deionization unit

sop for Sanitization of Purified Water Loop

sop for preparation of sodium meta bisulphate solution

sop for Testing of Hardness of Soft Water