sop for Replacement Policy

1.0 Objective

To lay down a procedure replacement of filters and UV Lights.

2.0 Scope

This Standard Operating Procedure is applicable for the procedure involved in the replacement of filters (i.e. Fresh Air Filter Riser filter, Pre filter, Fine filter, HEPA Filter), and UV Lights of the following Equipment to be followed at formulation plants

Filters

S.No EQUIPMENT NAME Types of filters

1 Air Handling Unit Riser Filters, Fresh Air Filters, Pre Filter, Micro Vee filter, HEPA Filters

2 Ventilation system Pre Filter Micro Vee filter

4 Dust extraction system cartridge filter

5 APUs of Fluid bed dryer Pre Filter, Micro Vee filter, HEPA

6 APUs of Coating Machine Pre Filter, Micro Vee filter, HEPA

7 LAFs and RLAFs Pre Filter, Micro Vee filter, HEPA

8 UV Lights

Water system and its loops, All pass Boxes and Dress Cabinets

3.0 Responsibility

3.1 Officer / Executive Engineering shall be responsible for the execution of this procedure.

3.2 Engineering Manager shall be responsible for the implementation of this SOP.

3.3 Head QA/designee shall be responsible for the compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

No : Number

QA : Quality assurance

ER : Engineering

HEPA : High efficiency Particulate air filter

HVAC : Heating Ventilation and Air Conditioning

UV : Ultra Violet

5.0 Procedure

5.1 Repairing or cleaning of the HEPA filter shall not be carried out.

5.2 Replacement of Fresh Air Filter, Pre Filter Micro Vee filter and cartridge filter will be under following circumstances

5.2.1 Whenever any puncture is observed in the filter element during its inspection, replace the Filter in the respective location with the same specification of filter.

5.2.2 Whenever the filter frame found destructed from its original shape, replace the filter.

5.2.3 Whenever filter elements get permanently chocked due to accumulation of abnormal dust or fiber particles on the filter and that can not be removed by cleaning of filter as per the filter cleaning procedure, then replace the filters.

5.2.4 If the differential pressure of the respective area or Filters are fluctuated from the its Specified limit which may raise doubt regarding the performance of filter then check it visually. If the filter condition found unsatisfactory then replace it.

5.3 Replacement of HEPA Filter.

5.3.1 Whenever HEPA filter integrity test results found not within the limits of the acceptance criteria of HVAC validation Protocol.

5.3.2 Ensure the following points during replacement of filter.

5.3.2.1 During Replacement of HEPA filters due to above said criteria, same shall be replaced with proper change control procedure.

5.3.2.2 The filter replacement to be done when only the respective activity of area or equipment in stop condition.

5.3.2.3 Dispose off the damaged filter, as per SOP No-ER/088-00.of Disposal procedure of engineering waste.

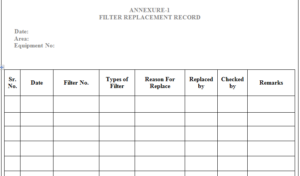

5.3.2.4 Make the necessary entry in filter replacement record.

5.3.2.5 Perform the test of respective filters and areas as SOP for HVAC Validation.

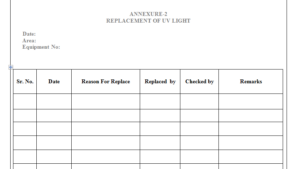

5.3.3 Procedure for UV Lights

5.3.3.1 Removing:

5.3.3.1.1.1 Switch off the mains of UV tube.

5.3.3.1.1.2 Remove UV tube by opening the threaded plug provided at the end of system.

5.3.3.1.2 Slowly pull of the UV tube and disconnect the electrical wires.

5.3.3.1.3 Keep UV tube at the safe area.

5.3.3.2 Fixing:

5.3.3.2.1 Connect the electrical wires to new UV tube.

5.3.3.2.1.1 Slowly insert the UV tube inside the jacket system and direct it to get fixed inside the holder.

5.3.3.2.1.2 Plug the system by closing the thread.

5.3.3.3 Frequency

5.3.3.3.1 Once after 7500 Hrs or when lamp damaged.

6.0 Forms and Records

6.1 Filter Replacement Record – Annexure-1

6.2 Replacement of UV Light – Annexure-2

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Controlled copies – Engineering Department

sop for Execution of Preventive Maintenance

Preparation of Sodium Hydroxide Solution

sop for water cooled chiller operation

cleaning and preventive maintenance of LAF and RLAF

sop for replacement of water system filters

cleaning and preventive maintenance of insectocutor

sop for operation of preventive maintenance

sop for material receiving and consumption record

sop for Preventive maintenance of bottle washing machine

sop for Replacement of Battery of Electronic Devices

sop for Preparation of R.O. Antiscalant Solution

Preventive Maintenance of Rapid Cooling Steam Sterilizer

Preventive Maintenance of Rapid cooling steam Generator

sop for Preventive Maintenance of Dust Collector

sop for Replacement of HVAC filters

SOP for Battery Backup in Mobile Laminar Air Flow Trolley

sop for Replacement of Tube lights

sop for Replacement of UV light of purified water plant

sop for Cleaning of soft water storage tank and RO feed tank

sop for Preparation of Sodium hydroxide Solution

sop for Operation and regeneration of softener plant

Procedure Of Issuance Of material from Engineering Store

sop for Preventive Maintenance of Filter Press

sop for Preventive Maintenance of Sugar Transfer System

sop for Preventive Maintenance of Shrink Sleeve Machine

sop for Preventive Maintenance of ROPP Cap Elevator

sop for Preventive Maintenance of Liquid Transfer Pumps

sop for Preventive Maintenance of Liquid Tanks

Preventive Maintenance of Strip De-Foiling Machine

sop for Preventive Maintenance of Colloidal Mill

sop for Preventive Maintenance of Packing Collator Belt

sop for Checking light intensity

sop for Operation of Fire- Extinguisher

sop for Passivation of WFI Distribution Loop

sop for Analysis of Effluent Treatment Plant Water

sop for Methodology to Dispose ETP Sludge

sop for Action Plan In Case Of Electrical Power Failure

sop for Colour Coding of Piping and Accessories of Utilities

sop for Disposal of Engineering Waste

Filter Cleaning of HVAC System RLAF & LAF

Procedure for Calibration of Magnehelic Gauge

Procedure for Calibration of Vacuum Gauge

Procedure for Calibration of Pressure Gauge

sop for Procedure for Calibration of Temperature Controller

sop for Preventive Maintenance of Infrared Dryer Umbrella Type

sop for Preventive Maintenance of Battery stacker

sop for Preventive Maintenance of Lift

sop for Preventive Maintenance of Vacuum Cleaner

sop for Preventive Maintenance of laminar air flow unit

sop for Preventive Maintenance of Lozenges Manufacturing Line

sop for Preventive Maintenance of Garment Washing Machine

sop for Preventive Maintenance of Multi Column Distillation Plant

sop for Preventive Maintenance of Steam Sterilizer Autoclave

sop for Preventive Maintenance of Pure steam Generator

sop for Preventive maintenance of Depyrogenating Tunnel

sop for Preventive Maintenance of vial sealing machine

sop for preventive maintenance of Powder Filling and Rubber Stoppering machine

sop for Preventive Maintenance of Vial Washing Machine

sop for Preventive Maintenance of Inspection Table

sop for Preventive Maintenance of Hi-Cart

sop for Preventive Maintenance of Turn table

sop for Preventive Maintenance of sticker labeling machine

sop for Preventive Maintenance of Liquid Filling and Sealing Machine

sop for Preventive Maintenance of Linear Bottle Washing Machine

sop for Preventive Maintenance of De-Foiling Machine

sop for Preventive Maintenance of Strip Packing Machine

sop for Preventive Maintenance of Blister Packing Machine

sop for Preventive Maintenance of Capsule Polishing and Sorting Machine

sop for Preventive Maintenance of Capsule Filling Machine

sop for Preventive maintenance of Auto Coater

sop for Preventive Maintenance of Compression Machine

sop for preventive maintenance of packing conveyor belt

sop for Preventive Maintenance of Sifter Cum Multi mill

sop for Preventive Maintenance of Rapid Mixer Granulator

sop for Preventive Maintenance Of Fluid Bed Dryer

sop for Preventive Maintenance of Octagonal Blender

sop for Preventive Maintenance of Lifting and Positioning Device

sop for Preventive Maintenance of Paste Preparation vessel

sop for preventive maintenance of Vibro-Sifter

sop for preventive maintenance of air curtain

sop for preventive maintenance of air handling units

Preventive Maintenance of Diesel Generator

sop for Preventive Maintenance of cooling towers

sop for Preventive Maintenance of Boiler

sop for Preventive Maintenance of Air Compressor

sop for Preventive Maintenance of Chilling Plant

sop for Preventive Maintenance of Transformers

sop for Preventive maintenance of Purified Water System

sop for Break Down maintenance of Machine and Work Requisition

sop for Operation of Dust Extraction System

sop for Operation Of Effluent Treatment Plant

sop for Operation Of Diesel Generator

sop for Operation of Multi Column Distillation Plant

sop for Operation of Pure Steam Generator

sop for Operation of Air Handling Unit

sop for Operation of Cooling Tower

sop for Operation of Air Compressor

sop for Operation of Water Chilling Plant

sop for Cleaning of Pure Steam Generator

Cleaning of Over Head Water Tanks HDPE

sop for Cleaning of Water tanks

sop for Sanitization of multi column plant

sop for Sanitization of Ultrafiltration System

Sop for Chemical Sanitization of Reverse Osmosis

Sop for Sanitization of Hot Sanitization & Electro Deionization unit

sop for Sanitization of Purified Water Loop

sop for preparation of sodium meta bisulphate solution

sop for Testing of Hardness of Soft Water