sop for Area Validation

1.0 Objective

To lay down a procedure to organize HVAC area validation activities & to conduct area validation of HVAC system

2.0 Scope

This Standard Operating Procedure is applicable for area validation to follow at formulation

plants

following areas:

2.1 Tablet & Capsule Area.

2.2 Liquid & Lozenges.

2.3 Micro area.

2.4 DPI area

3.0 Responsibility

3.1 Officer / Executive Engineering shall be responsible for the execution of this procedure.

3.2 Engineering Manager shall be responsible for the implementation of this SOP.

3.3 Head QA/ designee shall be responsible for compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

No : Number

NA : Not Applicable

QA : Quality assurance

Sr. No. : Serial number

OC : Out of calibration

SEP : Standard Engineering Procedure

HEPA : High efficiency particulate air

FPM : Feet per minute

5.0 Procedure

5.1 The engineering department shall identify the agencies/personnel who is capable of carry out HVAC validation services.

5.2 Screen the agencies for capability and qualifications.

5.3 Validation of HVAC system should be carried out through approved external agencies. The Vendor should bring all required validation master Instruments at site for validating HVAC system. The master instrument includes following.

5.3.1 Laser Particle Counter

5.3.2 Anemometer

5.3.3 Aerosol Generator

5.3.4 Sling Psychrometer.

5.3.5 Aerosol Photometer.

5.4 The vendor shall be selected based on technical qualification, experience, infrastructure facility, confidence level. Verification of traceability of master instruments.

5.5 The vendor shall be audited & evaluated for adherence of HVAC validation requirements, traceability, suitability of validation methods, & documentation practice.

5.6 There shall be written Agreement between vendor & company.

5.7 The vendor shall provide written validation procedure to various types of Instruments. This procedure shall be reviewed & approved by engineering manager.

5.8 The scope of HVAC validation activities is as follow

5.8.1 Verification of air changes of all process area, Quality & warehouse.

5.8.2 Integrity testing of HEPA filter.

5.8.3 Particle count report of all process area under static condition.

5.8.4 Recovery studies.

5.9 The engineering person shall witness validation activity.

5.10 The frequency & acceptance criteria of HVAC validation is as per Master Validation Plan/Protocol.

5.11 Integrity test of HEPA filter shall be carried out by Introducing an aerosol challenge upstream of filter and scanning immediately down stream of filter & support frame. It is carried out by using aerosol generator. This procedure detects any leakage in the HEPA filter media, frame & gasket seal.

5.12 Particle count in the designated area is carried out by using particle counter. The test is carried out under static condition. Before conducting particle count study, ensure that all components of clean room system which contribute its operation (air handling units, filtration system, walls, ceiling, and floor) are completed & functioning in accordance with the clean room requirements. The number of test points and their location should be chosen to satisfy statistical requirement of the area.

5.13 The report of the particle count should cover following points

5.13.1 Particle size Range.

5.13.2 The volume of air sampled.

5.13.3 The particle count

5.13.4 Time

5.13.5 The sampling point locations

5.13.6 The particle data shall be indicated in the form of No. of particle per cubic feet or cubic meter.

5.14 During validation if area do not meet acceptance criteria, revalidation to be carried out. If area fails in revalidation,

complete investigation to be carried out the performance of blower, motor, cooling coils, ducts micro-vee filter shall be checked.

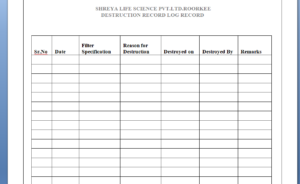

If required, HEPA filter shall be replaced. Replacement of HEPA filter record shall be maintained.

Failure instrument destruction record shall be maintained as per format No In case of failure of acceptance

criteria in area validation, evaluation of the impact of (OC) out of calibration measurement on product shall be evaluated.

In such cases all products which are manufactured in that area from last date of area validation shall be evaluated.

The report failure of area shall be made by engineering manager to production manager for Initiating product evaluation.

The production and quality department shall be responsible for review of product manufactured in that area where “area validation failed.”

5.15 Entry of validation to be made in area validation register as per format No Validation shall be maintained.

5.16 Engineering & Quality Assurance department is authorized to accept or reject validation contract in case of any deviation.

5.17 The area validation activity to be performed by outside approved agencies. After performing validation the approved contract agencies should submit certificate. The validation certificate should cover( Not limited to ) following points

5.17.1 Name of the Area & Room identifications

5.17.2 AHU System No

5.17.3 Filter area

5.17.4 Minimum 05 air Velocity reading in FPM.

5.17.5 Percentage of DOP / PAO Penetration.

5.17.6 Master instrument specification used for calibration.

5.17.7 Traceability certificate details.

5.17.8 Specification of master Instrument like Aerosol Photometer, Anemometer etc. With its calibration traceability & calibration due date.

5.17.9 Test standard code of ISO.

5.17.10 Particle count report, indicating meeting acceptance criteria as per ISO-14644-1.

5.18 The HVAC area validation certificate issued by contractor shall be reviewed and approved by Engineering Manager.

5.19 The periodic review shall be carried out during self inspection following points shall be considered in the periodic review.

5.19.1 HVAC Area validation system.

5.19.2 Planning for validation in case of addition of new facility.

5.19.3 Validation procedures.

5.19.4 HVAC validation frequency.

5.19.5 Traceability.

5.19.6 Environmental condition during validations.

5.19.7 Training needs.

5.20 The report of particle count, HEPA filter Integrity, verification of air changes, air flow pattern & recovery study summary report based on outside contractor certificate shall be recorded by executive- engineer as per format.

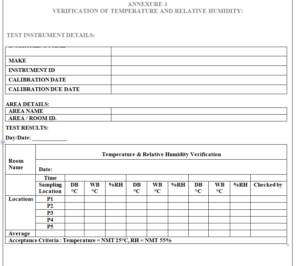

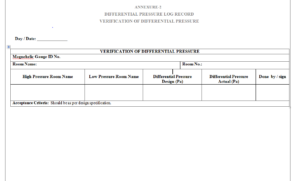

5.21 The report of temperature, relative humidity & differential pressure shall be recorded at beginning of the shift & after every four hours by production Executive of respective area as per format no. .

6.0 Forms and Records

6.1 Temperature & Relative Humidity Log Record – Annexure-1

6.2 Differential pressure Log Record – Annexure-2

6.3 Verification of air changes Log Record – Annexure-3

6.4 Destruction Record Log Record – Annexure-4

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Controlled copies – Engineering department

sop for Execution of Preventive Maintenance

Preparation of Sodium Hydroxide Solution

sop for water cooled chiller operation

cleaning and preventive maintenance of LAF and RLAF

sop for replacement of water system filters

cleaning and preventive maintenance of insectocutor

sop for operation of preventive maintenance

sop for material receiving and consumption record

sop for Preventive maintenance of bottle washing machine

sop for Replacement of Battery of Electronic Devices

sop for Preparation of R.O. Antiscalant Solution

Preventive Maintenance of Rapid Cooling Steam Sterilizer

Preventive Maintenance of Rapid cooling steam Generator

sop for Preventive Maintenance of Dust Collector

sop for Replacement of HVAC filters

SOP for Battery Backup in Mobile Laminar Air Flow Trolley

sop for Replacement of Tube lights

sop for Replacement of UV light of purified water plant

sop for Cleaning of soft water storage tank and RO feed tank

sop for Preparation of Sodium hydroxide Solution

sop for Operation and regeneration of softener plant

Procedure Of Issuance Of material from Engineering Store

sop for Preventive Maintenance of Filter Press

sop for Preventive Maintenance of Sugar Transfer System

sop for Preventive Maintenance of Shrink Sleeve Machine

sop for Preventive Maintenance of ROPP Cap Elevator

sop for Preventive Maintenance of Liquid Transfer Pumps

sop for Preventive Maintenance of Liquid Tanks

Preventive Maintenance of Strip De-Foiling Machine

sop for Preventive Maintenance of Colloidal Mill

sop for Preventive Maintenance of Packing Collator Belt

sop for Checking light intensity

sop for Operation of Fire- Extinguisher

sop for Passivation of WFI Distribution Loop

sop for Analysis of Effluent Treatment Plant Water

sop for Methodology to Dispose ETP Sludge

sop for Action Plan In Case Of Electrical Power Failure

sop for Colour Coding of Piping and Accessories of Utilities

sop for Disposal of Engineering Waste

Filter Cleaning of HVAC System RLAF & LAF

Procedure for Calibration of Magnehelic Gauge

Procedure for Calibration of Vacuum Gauge

Procedure for Calibration of Pressure Gauge

sop for Procedure for Calibration of Temperature Controller

sop for Preventive Maintenance of Infrared Dryer Umbrella Type

sop for Preventive Maintenance of Battery stacker

sop for Preventive Maintenance of Lift

sop for Preventive Maintenance of Vacuum Cleaner

sop for Preventive Maintenance of laminar air flow unit

sop for Preventive Maintenance of Lozenges Manufacturing Line

sop for Preventive Maintenance of Garment Washing Machine

sop for Preventive Maintenance of Multi Column Distillation Plant

sop for Preventive Maintenance of Steam Sterilizer Autoclave

sop for Preventive Maintenance of Pure steam Generator

sop for Preventive maintenance of Depyrogenating Tunnel

sop for Preventive Maintenance of vial sealing machine

sop for preventive maintenance of Powder Filling and Rubber Stoppering machine

sop for Preventive Maintenance of Vial Washing Machine

sop for Preventive Maintenance of Inspection Table

sop for Preventive Maintenance of Hi-Cart

sop for Preventive Maintenance of Turn table

sop for Preventive Maintenance of sticker labeling machine

sop for Preventive Maintenance of Liquid Filling and Sealing Machine

sop for Preventive Maintenance of Linear Bottle Washing Machine

sop for Preventive Maintenance of De-Foiling Machine

sop for Preventive Maintenance of Strip Packing Machine

sop for Preventive Maintenance of Blister Packing Machine

sop for Preventive Maintenance of Capsule Polishing and Sorting Machine

sop for Preventive Maintenance of Capsule Filling Machine

sop for Preventive maintenance of Auto Coater

sop for Preventive Maintenance of Compression Machine

sop for preventive maintenance of packing conveyor belt

sop for Preventive Maintenance of Sifter Cum Multi mill

sop for Preventive Maintenance of Rapid Mixer Granulator

sop for Preventive Maintenance Of Fluid Bed Dryer

sop for Preventive Maintenance of Octagonal Blender

sop for Preventive Maintenance of Lifting and Positioning Device

sop for Preventive Maintenance of Paste Preparation vessel

sop for preventive maintenance of Vibro-Sifter

sop for preventive maintenance of air curtain

sop for preventive maintenance of air handling units

Preventive Maintenance of Diesel Generator

sop for Preventive Maintenance of cooling towers

sop for Preventive Maintenance of Boiler

sop for Preventive Maintenance of Air Compressor

sop for Preventive Maintenance of Chilling Plant

sop for Preventive Maintenance of Transformers

sop for Preventive maintenance of Purified Water System

sop for Break Down maintenance of Machine and Work Requisition

sop for Operation of Dust Extraction System

sop for Operation Of Effluent Treatment Plant

sop for Operation Of Diesel Generator

sop for Operation of Multi Column Distillation Plant

sop for Operation of Pure Steam Generator

sop for Operation of Air Handling Unit

sop for Operation of Cooling Tower

sop for Operation of Air Compressor

sop for Operation of Water Chilling Plant

sop for Cleaning of Pure Steam Generator

Cleaning of Over Head Water Tanks HDPE

sop for Cleaning of Water tanks

sop for Sanitization of multi column plant

sop for Sanitization of Ultrafiltration System

Sop for Chemical Sanitization of Reverse Osmosis

Sop for Sanitization of Hot Sanitization & Electro Deionization unit

sop for Sanitization of Purified Water Loop

sop for preparation of sodium meta bisulphate solution

sop for Testing of Hardness of Soft Water

sop for Operation & back wash of multi grade filter

sop for testing of chlorine contents in water