sop for Break Down maintenance of Machine and Work Requisition

1.0 Objective

To lay down a procedure for Maintenance Work Requisition.

2.0 Scope

This SOP is applicable for raising Work Request by all users department in case of following situations to follow at formulation plants

Procedure for rectification of breakdown of equipment and other work request which shall be raised by the concerned department. The rectification of breakdown and other work request shall be carried by engineering department as per laid down procedure.

2.1 Requisition of civil repair related to plumbing/painting/door repairs.

2.2 Non performance of any system related to HVAC, Water, Air, and dust extraction etc.

2.3 Breakdown of utility equipments.

2.4 Rectification of electrical failures.

2.5 Any other work requisition related to process area.

3.0 Responsibility

3.1 Officer / Executive Engineering shall be responsible for the execution of this procedure.

3.2 Engineering Manager shall be responsible for the implementation of this SOP.

3.3 Head QA/designee shall be responsible for the compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

DPI : Dry Powder Injection

TCA : Tablet capsules

No : Number

QA : Quality Assurance

IPQA : In Production Quality Assurance

5.0 Procedure

5.1 When there is any break down of Machine / Equipment/ System or civil related work like Plumbing, Painting and Carpentry etc. The concerned/user department personnel shall raise the maintenance work request as per the Annexure –1.

5.2 The QA/IPQA personal will see the nature of break down; anticipate the fault and corrective action should be planned in co-ordination with Engineering and the representative (Officer/ Executive) of the concerned department.

5.3 Types of breakdown

5.4 Non Critical Breakdown: Which causes deviation to standard operating condition, but do not have a potential to give an impact on product.

5.5 Critical Breakdown: The breakdown which has potential to effect the product, this type of breakdown should be intimated immediately to QA Head and Engineering Head. and

5.6 If the breakdown is critical than the deviation/change control should be initiated/filled by the department.

5.7 User department should specify that machine is available for maintenance or not. If machine is in running condition user department should specify the time when the machine will be available for maintenance for engineering department.

5.8 Engineer should accept the intimation and inspect the machine& assign the respective technician.

5.9 Concerned user department shall fill the maintenance work request and send it to Engineering Department/Hand over to engineering person.

5.10 The engineer should inspect the machine, & take proper safety precaution prior to starting rectification job. If the work requires spares/lubricants, the same should be taken from stores after submitting material requisition to Engineering stores.

5.11 The engineer should raise material requisition as per purchase requisition if spares are not available in engineering store for repair/rectification.

5.12 If the breakdown maintenance work requires the skill of external agency, engineer from engineering department should discuss the same with Engineering Manager. The Engineering Head will co-ordinates with the external agency for rectification of work.

5.13 The engineer should supervise and coordinate with the outside contractor, if Job is to be done by out side contractor.

5.14 Outside contractor shall carry out the repair / rectification work in consultation with Nominated engineer from engineering department.

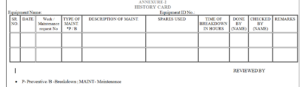

5.15 On satisfactory rectification check machine for smooth operation and take trial, technician / engineer have to Complete Maintenance work request as per Annexure- I.

5.16 The concern officer shall make entry of equipment failure in the respective equipment log failure and after rectification.

5.17 Repaired / rectified machine / equipment / system are handed over to the officer user department with his acknowledgement signature.

5.18 Periodic review of maintenance history shall be carried out every yearly the periodic review shall be recorded as per Annexure – I. The periodic review shall be conducted for following parameters.

5.18.1 Nature of breakdown

5.18.2 Nature of repeated Breakdown.

5.18.3 Action taken for prevention of breakdown.

5.19 The Intimation request of the breakdown shall be filed & stored in the respective Equipment files by Engineering Department.

5.20 The record of maintenance work carried out shall be maintained in the log book as per annexure -2.

5.21 Engineering head can review the maintenance work done.

6.0 Forms and Records

6.1 Format for maintenance work request – Annexure-1

6.2 Machine History Card – Annexure-2

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Controlled copies – Engineering Department.

Preparation of Sodium Hydroxide Solution

sop for water cooled chiller operation

cleaning and preventive maintenance of LAF and RLAF

sop for replacement of water system filters

cleaning and preventive maintenance of insectocutor

sop for operation of preventive maintenance

sop for material receiving and consumption record

sop for Preventive maintenance of bottle washing machine

sop for Replacement of Battery of Electronic Devices

sop for Preparation of R.O. Antiscalant Solution

Preventive Maintenance of Rapid Cooling Steam Sterilizer

Preventive Maintenance of Rapid cooling steam Generator

sop for Preventive Maintenance of Dust Collector

sop for Replacement of HVAC filters

SOP for Battery Backup in Mobile Laminar Air Flow Trolley

sop for Replacement of Tube lights

sop for Replacement of UV light of purified water plant

sop for Cleaning of soft water storage tank and RO feed tank

sop for Preparation of Sodium hydroxide Solution

sop for Operation and regeneration of softener plant

Procedure Of Issuance Of material from Engineering Store

sop for Preventive Maintenance of Filter Press

sop for Preventive Maintenance of Sugar Transfer System

sop for Preventive Maintenance of Shrink Sleeve Machine

sop for Preventive Maintenance of ROPP Cap Elevator

sop for Preventive Maintenance of Liquid Transfer Pumps

sop for Preventive Maintenance of Liquid Tanks

Preventive Maintenance of Strip De-Foiling Machine

sop for Preventive Maintenance of Colloidal Mill

sop for Preventive Maintenance of Packing Collator Belt

sop for Checking light intensity

sop for Operation of Fire- Extinguisher

sop for Passivation of WFI Distribution Loop

sop for Analysis of Effluent Treatment Plant Water

sop for Methodology to Dispose ETP Sludge

sop for Action Plan In Case Of Electrical Power Failure

sop for Colour Coding of Piping and Accessories of Utilities

sop for Disposal of Engineering Waste

Filter Cleaning of HVAC System RLAF & LAF

Procedure for Calibration of Magnehelic Gauge

Procedure for Calibration of Vacuum Gauge

Procedure for Calibration of Pressure Gauge

sop for Procedure for Calibration of Temperature Controller

sop for Preventive Maintenance of Infrared Dryer Umbrella Type

sop for Preventive Maintenance of Battery stacker

sop for Preventive Maintenance of Lift

sop for Preventive Maintenance of Vacuum Cleaner

sop for Preventive Maintenance of laminar air flow unit

sop for Preventive Maintenance of Lozenges Manufacturing Line

sop for Preventive Maintenance of Garment Washing Machine

sop for Preventive Maintenance of Multi Column Distillation Plant

sop for Preventive Maintenance of Steam Sterilizer Autoclave

sop for Preventive Maintenance of Pure steam Generator

sop for Preventive maintenance of Depyrogenating Tunnel

sop for Preventive Maintenance of vial sealing machine

sop for preventive maintenance of Powder Filling and Rubber Stoppering machine

sop for Preventive Maintenance of Vial Washing Machine

sop for Preventive Maintenance of Inspection Table

sop for Preventive Maintenance of Hi-Cart

sop for Preventive Maintenance of Turn table

sop for Preventive Maintenance of sticker labeling machine

sop for Preventive Maintenance of Liquid Filling and Sealing Machine

sop for Preventive Maintenance of Linear Bottle Washing Machine

sop for Preventive Maintenance of De-Foiling Machine

sop for Preventive Maintenance of Strip Packing Machine

sop for Preventive Maintenance of Blister Packing Machine

sop for Preventive Maintenance of Capsule Polishing and Sorting Machine

sop for Preventive Maintenance of Capsule Filling Machine

sop for Preventive maintenance of Auto Coater

sop for Preventive Maintenance of Compression Machine

sop for preventive maintenance of packing conveyor belt

sop for Preventive Maintenance of Sifter Cum Multi mill

sop for Preventive Maintenance of Rapid Mixer Granulator

sop for Preventive Maintenance Of Fluid Bed Dryer

sop for Preventive Maintenance of Octagonal Blender

sop for Preventive Maintenance of Lifting and Positioning Device

sop for Preventive Maintenance of Paste Preparation vessel

sop for preventive maintenance of Vibro-Sifter

sop for preventive maintenance of air curtain

sop for preventive maintenance of air handling units

Preventive Maintenance of Diesel Generator

sop for Preventive Maintenance of cooling towers

sop for Preventive Maintenance of Boiler

sop for Preventive Maintenance of Air Compressor

sop for Preventive Maintenance of Chilling Plant

sop for Preventive Maintenance of Transformers

sop for Preventive maintenance of Purified Water System

sop for Break Down maintenance of Machine and Work Requisition

sop for Operation of Dust Extraction System

sop for Operation Of Effluent Treatment Plant

sop for Operation Of Diesel Generator

sop for Operation of Multi Column Distillation Plant

sop for Operation of Pure Steam Generator

sop for Operation of Air Handling Unit

sop for Operation of Cooling Tower

sop for Operation of Air Compressor

sop for Operation of Water Chilling Plant

sop for Cleaning of Pure Steam Generator

Cleaning of Over Head Water Tanks HDPE

sop for Cleaning of Water tanks

sop for Sanitization of multi column plant

sop for Sanitization of Ultrafiltration System

Sop for Chemical Sanitization of Reverse Osmosis

Sop for Sanitization of Hot Sanitization & Electro Deionization unit

sop for Sanitization of Purified Water Loop

sop for preparation of sodium meta bisulphate solution

sop for Testing of Hardness of Soft Water

sop for Operation & back wash of multi grade filter

sop for testing of chlorine contents in water