sop for Building Maintenance

1.0 Objective

To lay down a procedure the Building Maintenance.

2.0 Scope

This Standard Operating Procedure is applicable for Building Maintenance to be followed at formulation plants

3.0 Responsibility

3.1 Officer / Executive Engineering shall be responsible for the execution of this procedure.

3.2 Engineering Manager shall be responsible for the implementation of this SOP.

3.3 Head QA/designee shall be responsible for compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

QA : Quality Assurance

EN : Engineering

5.0 Procedure

5.1 All jobs should be identified and listed.

5.2 All jobs which are part of plant building maintenance are to be estimated.

5.3 An authorized work order shall be raised in favor of the external agencies to carry out such work. Work order shall be suitable handed over to external agencies found competent to handle such Works.

5.4 In case of any of the Maintenance work is required to be carried out in core processing areas, material storage areas or quality control department, the departments shall be suitably informed in advance and take work permit from QA dept.

5.5 The areas shall be cleared of products, raw material, intermediate or Suitable measures shall be adapted to avoid any possible hazards to the product in Manufacture.

5.6 All major activities to be carried out as classified, Below:

5.6.1 All painting works shall be carried out by external agencies under supervision of Engineering Department Personnel.

5.6.2 All shades and grade of paints used and applied shall be pre-approved as per the Order issued for the work.

5.6.3 following grades are specified in various areas:

• External plant building walls Snowcem Walls

• Warehouse: Oil Bound Distemper (OBD)

• Production core areas: – Poly Urethane paint.

• Production Wash Areas: – Poly Urethane paint.

• External corridors/packing hall QC & other Oil Bound Distemper (OBD )

5.6.4 Flooring

5.6.4.1 All flooring works shall be carried out by external agencies under Supervision of Engineering Department Personnel.

5.6.4.2 All shades and grade of flooring used and applied shall be pre- approved as per the work order issued for the work.

5.6.4.3 The following grades are specified in various areas

5.6.4.3.1 Warehouse/production corridor epoxy resin.

5.6.4.3.2 Production area &corridor (core area) :- epoxy resin

5.6.4.3.3 Secondary packing Area/Primary change room:- epoxy QC/Administration/Canteen: – ceramic tile.

5.6.5 False Ceiling

5.6.5.1 All false ceiling works shall be carried out by external agencies under Supervision of Engineering Department Personnel.

5.6.5.2 All shades and grade of false ceiling used and applied shall be pre- Approved as per the work order issued for the work.

5.6.5.3 The following grades are specified in various areas:

5.6.5.3.1 Administration Department :- HILEX Board

5.6.5.3.2 Quality Control Area: – Gypsum Board.

5.6.5.3.3 TAC, DPI, Liquid & Lozenges Area- Laminated Gypsum Board

5.6.6 Coving

5.6.6.1 All coving jobs shall be carried out by external agencies under supervision of Engineering Department Personnel.

5.6.6.2 All shades and grade of coving used and applied shall be pre-approved as per the work order issued for the work.

5.6.6.3 Coving wherever applicable shall be of Epoxy Resin with Epoxy Paint as per the pre-approved sample.

5.6.6.4 Plumbing and other sanitary ware.

5.6.6.5 All plumbing shall be carried out by external agencies under supervision of Engineering Department Personnel.

5.6.6.6 All shades and grade of plumbing accessories used shall be pre- approved as per the work order issued for the work plumbing. Job shall involved the Following.

• Checking of all taps & tap valves

• Checking of flush tap valves and urinal

• Checking and cleaning of wash basin drains

• Cleaning of grease traps in drain chamber

• Checking of storm drain lines and perforated drain covers

5.6.7 Doors & Partitions

5.6.7.1 All repairs works of doors and partitions shall be carried out by in house/external agency (If required) under supervision of engineering department personnel.

5.6.7.2 Repair of doors and partitions shall involve the following actions.

• Checking of door gaskets and door seals

• Checking and servicing of door closer.

• Inspection of glass and door handles.

• Checking and lubrication of door hinges.

• Inspection of door panes and joints

5.6.8 Street Lighting

5.6.8.1 Tube light maintenance and cleaning to be done by authorized person With supervision of Engineering Department Personnel.

5.6.8.2 All major and minor civil activities shall be carried out by external agencies under supervision of Engineering Department Personnel.

5.6.9 Other Civil Activities

5.6.9.1 All civil activities are categorized as jobs involving.

• construction of masonry or MS structure

• floor digging and soiling renovation of plant building

• renovation of plant building

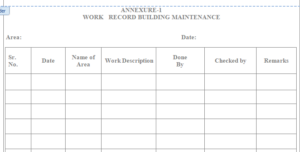

• Record the activities carried out in the Annexure

5.6.10 Frequencies:

5.6.10.1 All major activities as classified Above will be done frequency is :

|

DESCRIPTION |

FREQUENCY |

|

External Painting

|

Once in a five year

|

|

Filling and painting |

As and when required

|

| Touch up in core area | As and when required |

| Flooring and Coving | Yearly- repairs if necessary |

| Epoxy Touch up

|

As and when required

|

| Recoating of Epoxy | As and when required

|

|

False Ceiling |

Yearly-repairs if necessary |

| Crack filling and repair | as and when required |

| Coving: | Once in a Year or repairs if necessary |

| Plumbing and other sanitary | Quarterly or reported by user department |

| Door & partition | Quarterly or reported by user department |

| Street light (Cleaning) | Quarterly or reported by user department |

| Window cleaning | Quarterly or reported by user department of all area

|

| Civil Work | Once in a five year and repairs if necessary |

6.0 Forms and Records

6.1 Work Record of Building maintenance – Annexure-1

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Controlled copies – Engineering Department

Preparation of Sodium Hydroxide Solution

sop for water cooled chiller operation

cleaning and preventive maintenance of LAF and RLAF

sop for replacement of water system filters

cleaning and preventive maintenance of insectocutor

sop for operation of preventive maintenance

sop for material receiving and consumption record

sop for Preventive maintenance of bottle washing machine

sop for Replacement of Battery of Electronic Devices

sop for Preparation of R.O. Antiscalant Solution

Preventive Maintenance of Rapid Cooling Steam Sterilizer

Preventive Maintenance of Rapid cooling steam Generator

sop for Preventive Maintenance of Dust Collector

sop for Replacement of HVAC filters

SOP for Battery Backup in Mobile Laminar Air Flow Trolley

sop for Replacement of Tube lights

sop for Replacement of UV light of purified water plant

sop for Cleaning of soft water storage tank and RO feed tank

sop for Preparation of Sodium hydroxide Solution

sop for Operation and regeneration of softener plant

Procedure Of Issuance Of material from Engineering Store

sop for Preventive Maintenance of Filter Press

sop for Preventive Maintenance of Sugar Transfer System

sop for Preventive Maintenance of Shrink Sleeve Machine

sop for Preventive Maintenance of ROPP Cap Elevator

sop for Preventive Maintenance of Liquid Transfer Pumps

sop for Preventive Maintenance of Liquid Tanks

Preventive Maintenance of Strip De-Foiling Machine

sop for Preventive Maintenance of Colloidal Mill

sop for Preventive Maintenance of Packing Collator Belt

sop for Checking light intensity

sop for Operation of Fire- Extinguisher

sop for Passivation of WFI Distribution Loop

sop for Analysis of Effluent Treatment Plant Water

sop for Methodology to Dispose ETP Sludge

sop for Action Plan In Case Of Electrical Power Failure

sop for Colour Coding of Piping and Accessories of Utilities

sop for Disposal of Engineering Waste

Filter Cleaning of HVAC System RLAF & LAF

Procedure for Calibration of Magnehelic Gauge

Procedure for Calibration of Vacuum Gauge

Procedure for Calibration of Pressure Gauge

sop for Procedure for Calibration of Temperature Controller

sop for Preventive Maintenance of Infrared Dryer Umbrella Type

sop for Preventive Maintenance of Battery stacker

sop for Preventive Maintenance of Lift

sop for Preventive Maintenance of Vacuum Cleaner

sop for Preventive Maintenance of laminar air flow unit

sop for Preventive Maintenance of Lozenges Manufacturing Line

sop for Preventive Maintenance of Garment Washing Machine

sop for Preventive Maintenance of Multi Column Distillation Plant

sop for Preventive Maintenance of Steam Sterilizer Autoclave

sop for Preventive Maintenance of Pure steam Generator

sop for Preventive maintenance of Depyrogenating Tunnel

sop for Preventive Maintenance of vial sealing machine

sop for preventive maintenance of Powder Filling and Rubber Stoppering machine

sop for Preventive Maintenance of Vial Washing Machine

sop for Preventive Maintenance of Inspection Table

sop for Preventive Maintenance of Hi-Cart

sop for Preventive Maintenance of Turn table

sop for Preventive Maintenance of sticker labeling machine

sop for Preventive Maintenance of Liquid Filling and Sealing Machine

sop for Preventive Maintenance of Linear Bottle Washing Machine

sop for Preventive Maintenance of De-Foiling Machine

sop for Preventive Maintenance of Strip Packing Machine

sop for Preventive Maintenance of Blister Packing Machine

sop for Preventive Maintenance of Capsule Polishing and Sorting Machine

sop for Preventive Maintenance of Capsule Filling Machine

sop for Preventive maintenance of Auto Coater

sop for Preventive Maintenance of Compression Machine

sop for preventive maintenance of packing conveyor belt

sop for Preventive Maintenance of Sifter Cum Multi mill

sop for Preventive Maintenance of Rapid Mixer Granulator

sop for Preventive Maintenance Of Fluid Bed Dryer

sop for Preventive Maintenance of Octagonal Blender

sop for Preventive Maintenance of Lifting and Positioning Device

sop for Preventive Maintenance of Paste Preparation vessel

sop for preventive maintenance of Vibro-Sifter

sop for preventive maintenance of air curtain

sop for preventive maintenance of air handling units

Preventive Maintenance of Diesel Generator

sop for Preventive Maintenance of cooling towers

sop for Preventive Maintenance of Boiler

sop for Preventive Maintenance of Air Compressor

sop for Preventive Maintenance of Chilling Plant

sop for Preventive Maintenance of Transformers

sop for Preventive maintenance of Purified Water System

sop for Break Down maintenance of Machine and Work Requisition

sop for Operation of Dust Extraction System

sop for Operation Of Effluent Treatment Plant

sop for Operation Of Diesel Generator

sop for Operation of Multi Column Distillation Plant

sop for Operation of Pure Steam Generator

sop for Operation of Air Handling Unit

sop for Operation of Cooling Tower

sop for Operation of Air Compressor

sop for Operation of Water Chilling Plant

sop for Cleaning of Pure Steam Generator

Cleaning of Over Head Water Tanks HDPE

sop for Cleaning of Water tanks

sop for Sanitization of multi column plant

sop for Sanitization of Ultrafiltration System

Sop for Chemical Sanitization of Reverse Osmosis

Sop for Sanitization of Hot Sanitization & Electro Deionization unit

sop for Sanitization of Purified Water Loop

sop for preparation of sodium meta bisulphate solution

sop for Testing of Hardness of Soft Water

sop for Operation & back wash of multi grade filter

sop for testing of chlorine contents in water