sop for Preventive Maintenance of Compression Machine

1.0 Objective

To lay down a procedure for the Preventive Maintenance of Compression Machine.

2.0 Scope

This Standard Operating Procedure is applicable for Preventive Maintenance of all Compression Machines to be followed at formulation plants

3.0 Responsibility

3.1 Officer / Executive Engineering shall be responsible for the execution of this procedure.

3.2 Engineering Manager shall be responsible for the compliance of this SOP.

3.3 Head QA/designee shall be responsible for the compliance of this SOP.

4.0 Abbreviations and Definitions

SOP : Standard Operating Procedure

No : Number

QA : Quality assurance

Qty : Quantity

St : Station

ER : Engineering

5.0 Procedure

5.1 General Conditions

5.1.1 Refer the master plan of preventive maintenance.

5.1.2 Equipment shall be available for preventive maintenance.

5.1.3 Clean oil / grease stains & remove unwanted material, spares after completion of work .

5.2 Precautions

5.2.1 Use necessary safety wears, while doing the work.

5.2.2 Ensure covers & guards are properly fixed.

5.3 Procedure for Preventive Maintenance of Compression Machine.

5.3.1 Ensure that electrical supply is in off position in main panel and display “Under Maintenance” Board on the panel board and inform all the concerned.

5.3.2 Operator or above has to ensure and verify the check points for the preventive maintenance as shown in the Annexure – 1,2 and 3 of this SOP.

5.3.3 After the completion of preventive maintenance, check the machine for smooth operation.

5.3.4 Remove “Under Maintenance” Board on the panel board after completion of the maintenance.

5.3.5 The operator / technician who perform the job will enter his name / sign in “DoneBy” Column and responsible Engineer/ Officer will put sign in “Checked by” column Department head will review the record every month.

5.3.6 Quarterly maintenance will include the jobs of monthly maintenance, half yearly Maintenance will include the jobs of monthly and quarterly maintenance.

5.3.7 Quarterly Preventive Maintenance is to be carried out as per the following check points:

5.3.7.1 Check the force feeder, motor & gear box for normal functioning. Check the Worm wheel & worm shaft, if worn out, replace it.

5.3.7.2 Check the force feeder impeller blades for normal free rotation. (If not proper, Check side clearance, check bearings, if worn, replaces and realigns the impeller Blades.

5.3.7.3 Check all adjustment rollers of tablet weight, thickness working (If not Check Adjusting nuts on the tie rods, check drive key, if parts are worn, replace Parts).

5.3.7.4 Check the working of automatic intermittent lubrication system. (If not Satisfactory, check oil level in the reservoir, check if the tubing is punctured, Replace the part). (Oil used is Enclo-68).

5.3.7.5 Check the Power pack assembly for normal functioning. (If not satisfactory).

5.3.7.6 Check the oil level in the reservoir through the oil level indicator). (Oil used is Enklo-32)(Note: Oil level is checked when the overload is set at zero pressure).

5.3.7.7 Check the clutch assembly for proper engagement/disengagement. (If any of the Parts/pads of the clutch assembly has worn, repair/replace it).

5.3.7.8 Check the free movement of compression rollers.

5.3.7.9 Check the all electrical terminal connections and tighten the same.

5.3.7.10 Check the variable speed pulley/belt for proper functioning (if the pulley is worn out, remove it & replace it, ensure that the pulley is lubricated). Also checks the belt for any wear/tear if needed replace the belt. (Ensure proper alignment in between drive pulley & driven pulley.)

5.3.7.11 Check the pressure adjustment assembly.(If any of the part is worn out, replace it).

5.3.7.12 Check belt pads/oil cups used for lubrication of punches.

5.3.7.13 Check the proper earthing.

5.3.8 Half Yearly Preventive Maintenance is to be carried out as per the following check points.

5.3.8.1 Check the main gear box/motor for normal operation. (If not proper, check the Bearings if worn replace it else lubricate them, check worm gear if worn out, Advisable to replace it). Top up Enklo-68 gear box oil in Gear box.

5.3.8.2 Check all interlocks of the machine for proper operation.

5.3.8.3 Check the electrical panel for any loose connection.(If observed tightened.

5.3.8.4 Check the all electrical controls, switches for normal working. (If observed).

6.0 Forms and Records

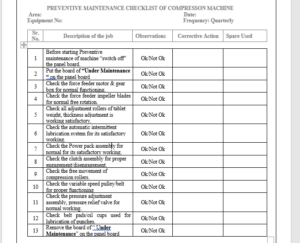

6.1 Quarterly Preventive Maintenance Check List of Compression Machine

6.2 Half Yearly Preventive Maintenance Check List of Compression Machine-

7.0 Distribution

7.1 Master copy – Documentation Cell (Quality Assurance)

7.2 Controlled copies – Engineering Department

Annexure

sop for Execution of Preventive Maintenance

Preparation of Sodium Hydroxide Solution

sop for water cooled chiller operation

cleaning and preventive maintenance of LAF and RLAF

sop for replacement of water system filters

cleaning and preventive maintenance of insectocutor

sop for operation of preventive maintenance

sop for material receiving and consumption record

sop for Preventive maintenance of bottle washing machine

sop for Replacement of Battery of Electronic Devices

sop for Preparation of R.O. Antiscalant Solution

Preventive Maintenance of Rapid Cooling Steam Sterilizer

Preventive Maintenance of Rapid cooling steam Generator

sop for Preventive Maintenance of Dust Collector

sop for Replacement of HVAC filters

SOP for Battery Backup in Mobile Laminar Air Flow Trolley

sop for Replacement of Tube lights

sop for Replacement of UV light of purified water plant

sop for Cleaning of soft water storage tank and RO feed tank

sop for Preparation of Sodium hydroxide Solution

sop for Operation and regeneration of softener plant

Procedure Of Issuance Of material from Engineering Store

sop for Preventive Maintenance of Filter Press

sop for Preventive Maintenance of Sugar Transfer System

sop for Preventive Maintenance of Shrink Sleeve Machine

sop for Preventive Maintenance of ROPP Cap Elevator

sop for Preventive Maintenance of Liquid Transfer Pumps

sop for Preventive Maintenance of Liquid Tanks

Preventive Maintenance of Strip De-Foiling Machine

sop for Preventive Maintenance of Colloidal Mill

sop for Preventive Maintenance of Packing Collator Belt

sop for Checking light intensity

sop for Operation of Fire- Extinguisher

sop for Passivation of WFI Distribution Loop

sop for Analysis of Effluent Treatment Plant Water

sop for Methodology to Dispose ETP Sludge

sop for Action Plan In Case Of Electrical Power Failure

sop for Colour Coding of Piping and Accessories of Utilities

sop for Disposal of Engineering Waste

Filter Cleaning of HVAC System RLAF & LAF

Procedure for Calibration of Magnehelic Gauge

Procedure for Calibration of Vacuum Gauge

Procedure for Calibration of Pressure Gauge

sop for Procedure for Calibration of Temperature Controller

sop for Preventive Maintenance of Infrared Dryer Umbrella Type

sop for Preventive Maintenance of Battery stacker

sop for Preventive Maintenance of Lift

sop for Preventive Maintenance of Vacuum Cleaner

sop for Preventive Maintenance of laminar air flow unit

sop for Preventive Maintenance of Lozenges Manufacturing Line

sop for Preventive Maintenance of Garment Washing Machine

sop for Preventive Maintenance of Multi Column Distillation Plant

sop for Preventive Maintenance of Steam Sterilizer Autoclave

sop for Preventive Maintenance of Pure steam Generator

sop for Preventive maintenance of Depyrogenating Tunnel

sop for Preventive Maintenance of vial sealing machine

sop for preventive maintenance of Powder Filling and Rubber Stoppering machine

sop for Preventive Maintenance of Vial Washing Machine

sop for Preventive Maintenance of Inspection Table

sop for Preventive Maintenance of Hi-Cart

sop for Preventive Maintenance of Turn table

sop for Preventive Maintenance of sticker labeling machine

sop for Preventive Maintenance of Liquid Filling and Sealing Machine

sop for Preventive Maintenance of Linear Bottle Washing Machine

sop for Preventive Maintenance of De-Foiling Machine

sop for Preventive Maintenance of Strip Packing Machine

sop for Preventive Maintenance of Blister Packing Machine

sop for Preventive Maintenance of Capsule Polishing and Sorting Machine

sop for Preventive Maintenance of Capsule Filling Machine

sop for Preventive maintenance of Auto Coater

sop for Preventive Maintenance of Compression Machine

sop for preventive maintenance of packing conveyor belt

sop for Preventive Maintenance of Sifter Cum Multi mill

sop for Preventive Maintenance of Rapid Mixer Granulator

sop for Preventive Maintenance Of Fluid Bed Dryer

sop for Preventive Maintenance of Octagonal Blender

sop for Preventive Maintenance of Lifting and Positioning Device

sop for Preventive Maintenance of Paste Preparation vessel

sop for preventive maintenance of Vibro-Sifter

sop for preventive maintenance of air curtain

sop for preventive maintenance of air handling units

Preventive Maintenance of Diesel Generator

sop for Preventive Maintenance of cooling towers

sop for Preventive Maintenance of Boiler

sop for Preventive Maintenance of Air Compressor

sop for Preventive Maintenance of Chilling Plant

sop for Preventive Maintenance of Transformers

sop for Preventive maintenance of Purified Water System

sop for Break Down maintenance of Machine and Work Requisition

sop for Operation of Dust Extraction System

sop for Operation Of Effluent Treatment Plant

sop for Operation Of Diesel Generator

sop for Operation of Multi Column Distillation Plant

sop for Operation of Pure Steam Generator

sop for Operation of Air Handling Unit

sop for Operation of Cooling Tower

sop for Operation of Air Compressor

sop for Operation of Water Chilling Plant

sop for Cleaning of Pure Steam Generator

Cleaning of Over Head Water Tanks HDPE

sop for Cleaning of Water tanks

sop for Sanitization of multi column plant

sop for Sanitization of Ultrafiltration System

Sop for Chemical Sanitization of Reverse Osmosis

Sop for Sanitization of Hot Sanitization & Electro Deionization unit

sop for Sanitization of Purified Water Loop

sop for preparation of sodium meta bisulphate solution

sop for Testing of Hardness of Soft Water